Lifetime Issues for Organic Polymer Light-Emitting Devices:

Encapsulation Schemes

Aaron R. Johnson and Jerzy Kanicki

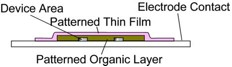

This project seeks to extend the lifetime of organic polymer light-emitting devices (PLEDs) by blocking the transmission of ambient oxygen and moisture in to the delicate emissive region of the device. Our approach is to encapsulate the organic device with hybrid thin-film stacks of both organic and inorganic materials. It is projected that, for commercial applications, such an encapsulation scheme will need to reduce the water vapor transmission to 1x10-6 g/m2-day and the oxygen transmission to 1x10-5 cm3 (STP)/m2-day. This project seeks to extend the lifetime of organic polymer light-emitting devices (PLEDs) by blocking the transmission of ambient oxygen and moisture in to the delicate emissive region of the device. Our approach is to encapsulate the organic device with hybrid thin-film stacks of both organic and inorganic materials. It is projected that, for commercial applications, such an encapsulation scheme will need to reduce the water vapor transmission to 1x10-6 g/m2-day and the oxygen transmission to 1x10-5 cm3 (STP)/m2-day.

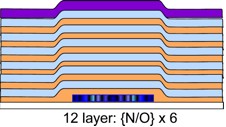

We have developed a low temperature (100C) PECVD (ltPECVD) process for both amorphous silicon nitride and amorphous silicon oxide layers which yield optically transparent layers (>85% transmission) with low stress (-1.6 x 109 dyne/cm2, -0.42 x 109 dyne/cm2, for nitride and oxide, respectively) and an index of refraction similar to thin films grown at higher temperatures (1.71, 1.8, for nitride and oxide, respectively). We have developed a low temperature (100C) PECVD (ltPECVD) process for both amorphous silicon nitride and amorphous silicon oxide layers which yield optically transparent layers (>85% transmission) with low stress (-1.6 x 109 dyne/cm2, -0.42 x 109 dyne/cm2, for nitride and oxide, respectively) and an index of refraction similar to thin films grown at higher temperatures (1.71, 1.8, for nitride and oxide, respectively).

The requirement for low temperature comes from the need for any encapsulation process to be commensurate with the delicate organic layers beneath. Many emissive polymers have relatively low glass transition temperatures and, as such, degrade quickly when exposed to high temperature. The low temperature deposition introduces a number of issues which must be dealt with in this project, including the formation of pinhole defects and the deposition of particulate matter. In this vein, we have begun to incorporate organic thin films in to the encapsulation schemes which, while they do not possess the barrier properties of inorganic films, do have the advantage of conformal coverage, which both seals in particulate matter as well as planarizes the encapsulating stack. The requirement for low temperature comes from the need for any encapsulation process to be commensurate with the delicate organic layers beneath. Many emissive polymers have relatively low glass transition temperatures and, as such, degrade quickly when exposed to high temperature. The low temperature deposition introduces a number of issues which must be dealt with in this project, including the formation of pinhole defects and the deposition of particulate matter. In this vein, we have begun to incorporate organic thin films in to the encapsulation schemes which, while they do not possess the barrier properties of inorganic films, do have the advantage of conformal coverage, which both seals in particulate matter as well as planarizes the encapsulating stack.

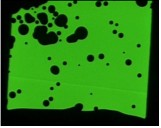

One difficulty arising from the low temperature PECVD processes is the formation of particulate matter on the surface of the PLED. This can be mitigated, somewhat, through an optimization of the PECVD recipes used to deposit films, but cannot be eliminated. The best solution, we have found, is to include an organic capping layer of parylene atop the deposited inorganic layers. The purpose of the organic capping layer is to seal in particulate matter so that it cannot be dislodged, leaving an exposed area for oxygen and moisture to enter the interior of the device. One difficulty arising from the low temperature PECVD processes is the formation of particulate matter on the surface of the PLED. This can be mitigated, somewhat, through an optimization of the PECVD recipes used to deposit films, but cannot be eliminated. The best solution, we have found, is to include an organic capping layer of parylene atop the deposited inorganic layers. The purpose of the organic capping layer is to seal in particulate matter so that it cannot be dislodged, leaving an exposed area for oxygen and moisture to enter the interior of the device.

This project is supported by Department of the Navy through eMagin Corporation.

top

|