EECS 373 Lab 7: Data Converters

Copyright © 2010-2011

Ye-Sheng Kuo,

Thomas Schmid,

Matt Smith,

Lohit Yerva,

and Prabal Dutta.

11/07/2011

Schedule

EECS

373 Fall 2011 Home Page

EECS

373 Labs Google Calendar

Introduction

As you might guess, with all the other goodies included in the

SmartFusion

MSS the folks at Actel did not forget ADC and DAC resources. The MSS

ACE (Analog Computing Engine) is relatively complex

component providing DAC/ADC functionality, sampling

control, analog threshold detection, filtering and DMA access just to

mention a few. Despite this apparent complexity, the ACE can be

relatively easy to use. The ACE like the other MSS components is

automatically interfaced to the peripheral bus and a user friendly GUI

is provided for configuration. Of course, a library of drivers is also

generated.

Objectives

The purpose of this lab is to...

- Learn how to configure the ACE for basic DAC and ADC operations.

- Learn to measure ADC quantization and typical transfer function

characteristics.

- Learn the basics of sampling by observing aliasing of sampled

sine wave.

- Learn how to build a simple audio amplifier.

- Sample and record an audio signal for playback using the ACE and

your audio amplifier.

Background

ADC Quantization and Transfer Function Characteristics

Quantizing error is inherent in most measurements

and limits the certainty of measurement. The quantizing error for

an ADC

is defined to be 1 LSB. It can also be expressed in volts or LSBv for

an n-bit

ADC .

Quantizing

error in

volts = voltage range of conversion/2^n

For our converter, the voltage range is 2.56

volts. If we program the ACE to be an 8 bit ADC, the quantizing

error in

milli-volts

will be

LSBv =

2.56 volts/2^8

= 10 mv

So, you can only know the value to 10 mv. The ideal quantum size of 1 LSB

can actually

vary to be larger or smaller from fabrication issues and other sources.

These

effects are characterized as integral non-linearity (INL) and

differential

non-linearity (DNL). Under normal

conditions

in the lab you will NOT observe this.

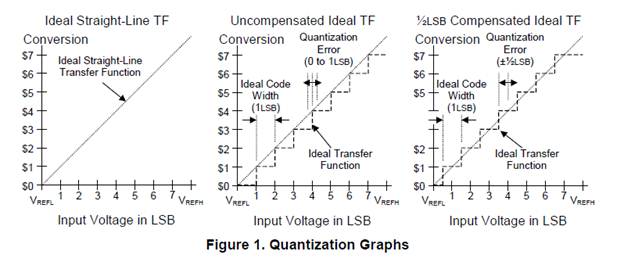

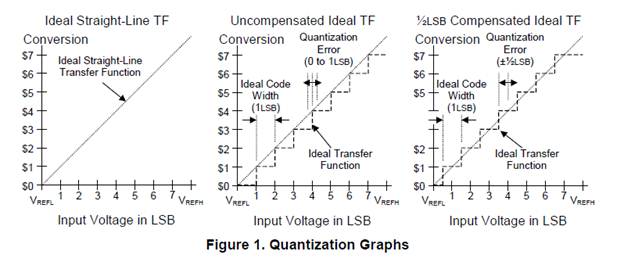

Plotting the conversion value against the analog

value

defines the ADC transfer characteristic or input to output

relationship.

The first graph shows the ideal transfer function

excluding

quantizing effects. The second case illustrates the affect of

quantizing resulting

in a stair case like transfer function. In this case the quantization

error is

from 0 LSB to 1 LSB. The last graph illustrates an ADC model that

shifts the

transfer function to center the quantizing error over the conversion

intervals.

In this case, the quantization error is +/-

½ LSB. In both cases the

quantizing error is 1 LSB, but the relationship of the conversion value

to the

input voltage is shifted by ½ LSB.

Sampling Basics

When converting relatively stable voltages to digital values a few

samples are sufficient to represent the voltage. However, when sampling

time varying signals the question arises, just how many samples are

required

to represent the signal. The Nyquist-Shannon sampling theorem predicts

that periodic signals can be reproduced when the original signal is

sampled at >= 2 times its period. If the signal is sampled at a rate

that is less than the 2 times its period, the reconstructed signal will

have a different frequency and shape. A simple predictor is given by

the following equation:

alias frequency = sampled signal

frequency - sampling frequency

The reconstructed

signal is commonly referred to as an alias and is a common problem in

applied signal processing. There are many topics forming the foundation

of signal processing, but

these basics should cover our needs for the present.

Additional Material

Overview

Pre-Lab Assignment

- Read through the lab 7 notes.

- Read through the data converter lecture.

In-Lab Assignment

- ADC/DAC Basics

- Aliasing, Quantization error, Smoothing filter

- Simple Audio system

In-Lab Assignment

Aliasing, Quantization error

Configuring the SmartFusion ACE

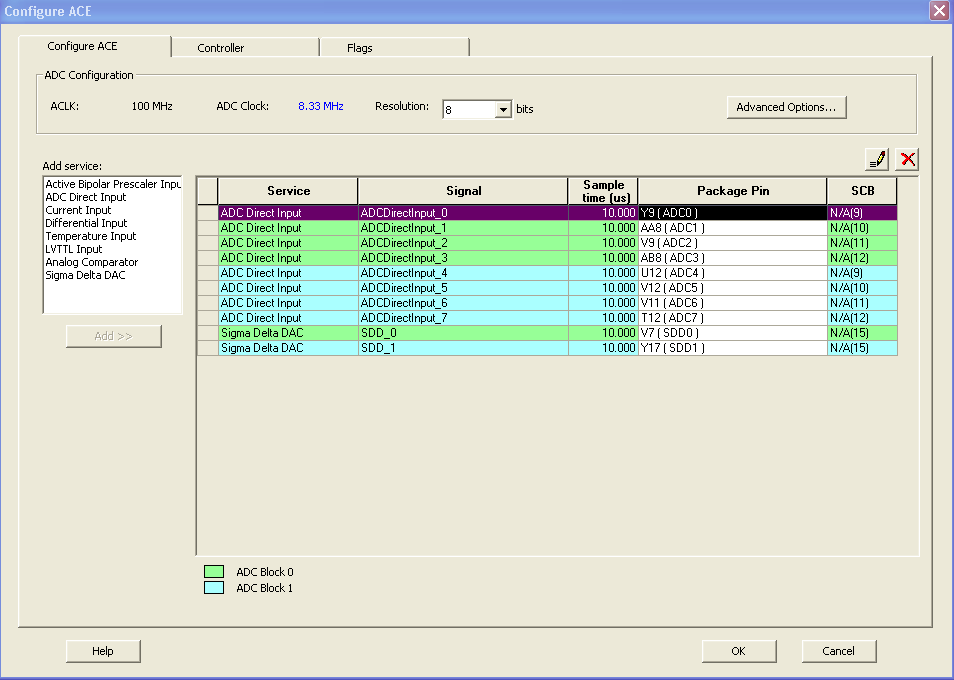

For this part of the lab we will configure the ACE component in the

MSS, synthesize, Place and Route and flash the FPGA. Disable

everything but the ACE and UART_0.

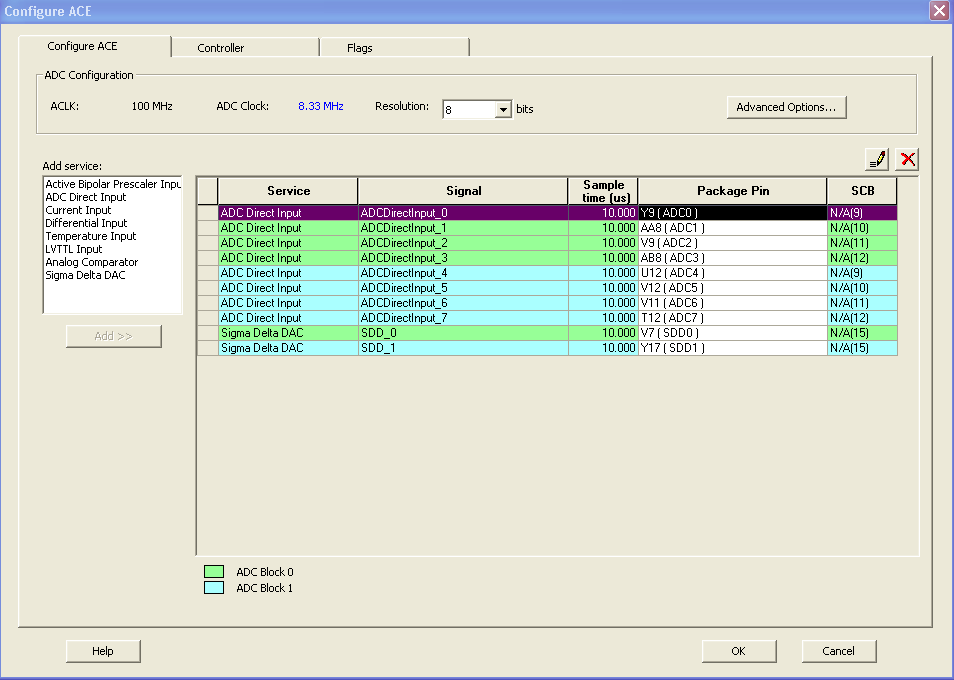

Each SmartFusion

Eval Kit has 10 direct analog input channel and 2 Sigma-delta DACs. We

want to use just one of each. Open the Libero, SmartDesign. Double

click ACE

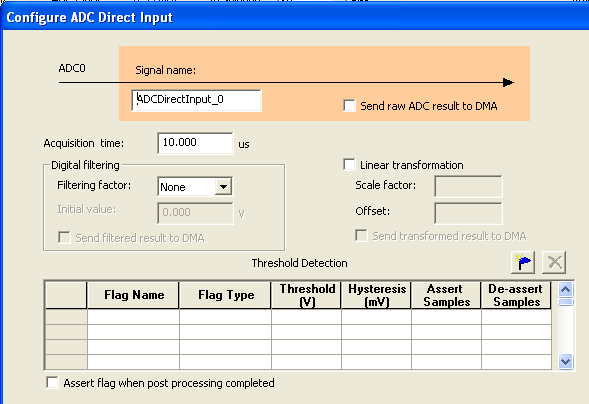

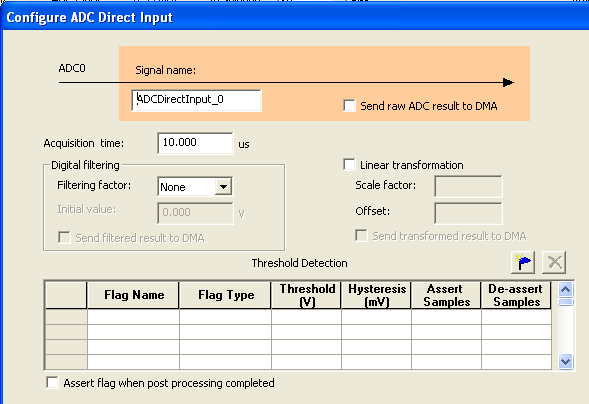

In left column, add a ADC Direct Input service. Put ADCDirectInput_0

in Signal Name and click OK. On the

top of configurator, set the resolution to 8 bits.

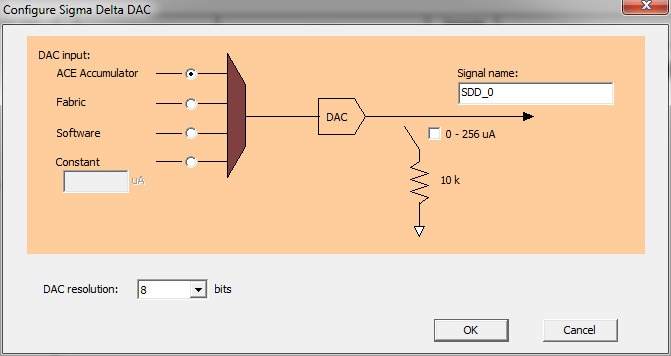

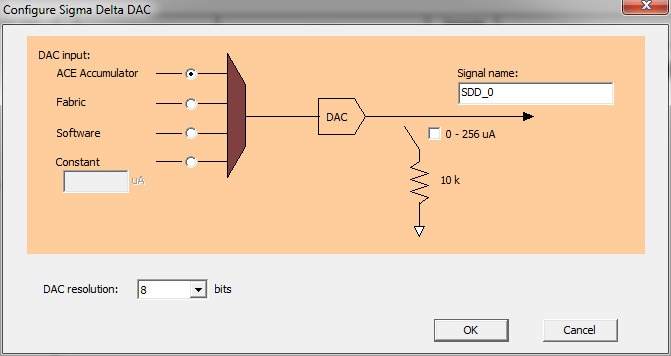

Add another Sigma Delta DAC service, select ACE Accumulator

as DAC input and

select the DAC resolution to 8 bits. Click OK.

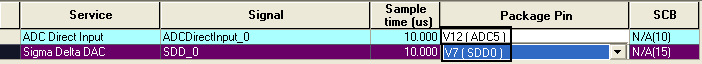

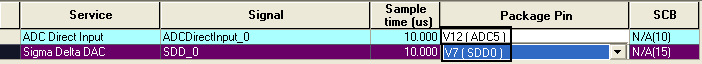

Set your ADC Direct Input Package Pin to V12 ( ADC5 ), and

Sigma Delta DAC Package

Pin to V7 ( SDD0 )

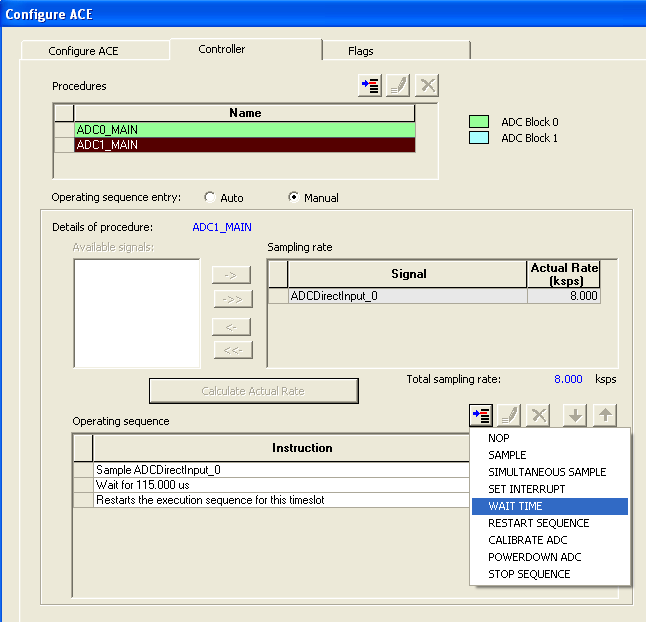

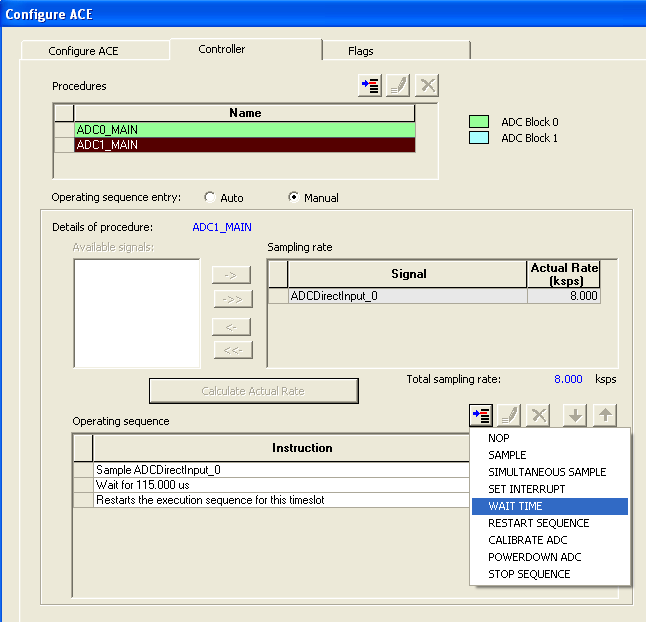

Go to Controller tab, select only ADC1_MAIN. Add all

Available

signals to sampling rate requirement. Click Calculate Sequence and

Actual Rate

Notice that the Total sampling rate should be 87.000 ksps. We

want to slow it down to 8 ksps.

Set the Operating sequence entry to Manual and insert a

WAIT TIME

operating sequence slot, using  ,

and configure it to 115us. Move the Wait

for 115.00us above Restarts the execution sequence for this

timeslot. Click Calculate Actual Rate.

The Actual Rate for ADC / DAC should be 8.000 ksps.

,

and configure it to 115us. Move the Wait

for 115.00us above Restarts the execution sequence for this

timeslot. Click Calculate Actual Rate.

The Actual Rate for ADC / DAC should be 8.000 ksps.

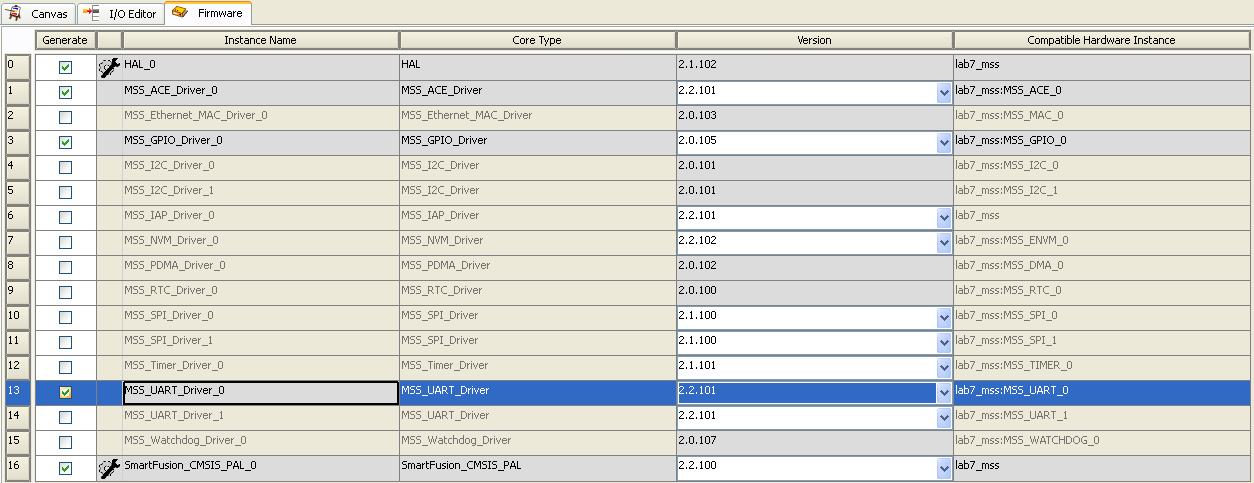

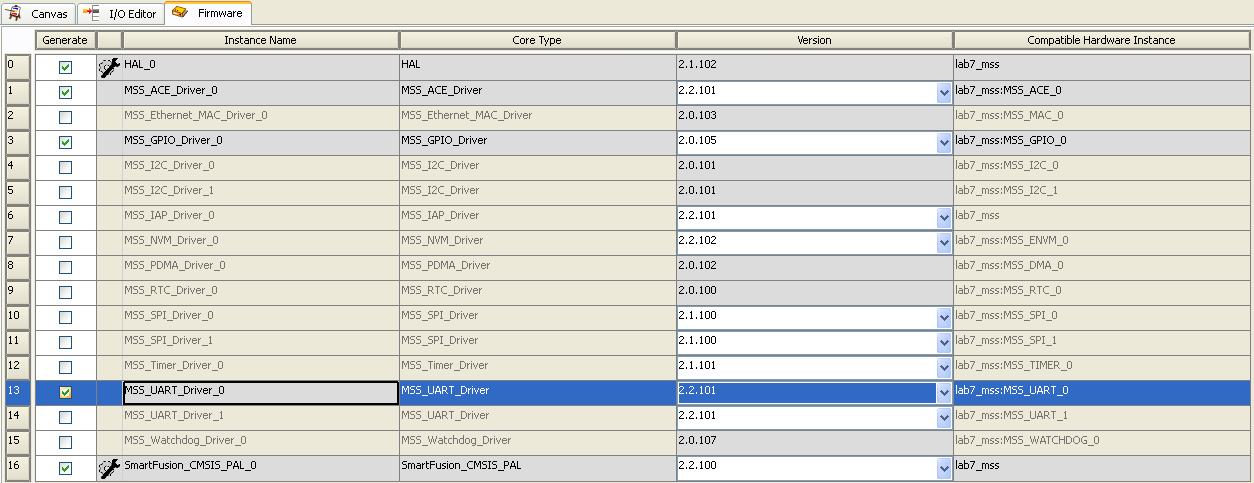

Click OK and go to Firmware tab. Check the UART, GPIO, and

ACE drivers.

Click Save and Generate. Put the IP core to canvas and

run the synthesis, place &

route and flash your SmartFusion.

A Simple ADC/DAC Application

Create a C project in Softconsole as you did before, set the linker

script, import the drivers. The following code reads the ADC

and write the DAC with the ADC conversion value

#include <stdio.h>

#include <inttypes.h>

#include "drivers/mss_ace/mss_ace.h"

#include "drivers/mss_uart/mss_uart.h"

ace_channel_handle_t adc_handler;

int main(){

ACE_init();

/* DAC initialization */

ACE_configure_sdd(

SDD1_OUT,

SDD_8_BITS,

SDD_VOLTAGE_MODE | SDD_RETURN_TO_ZERO,

INDIVIDUAL_UPDATE

);

ACE_enable_sdd(SDD1_OUT);

/* handler for ADC channel */

adc_handler = ACE_get_channel_handle((const uint8_t *)"ADCDirectInput_0");

while(1){

uint16_t adc_data = ACE_get_ppe_sample(adc_handler);

ACE_set_sdd_value(SDD1_OUT, (uint32_t)(adc_data>>4));

}

return 0;

}

Put the code in a main.c file. Compile the source code and launch

the debugger session.

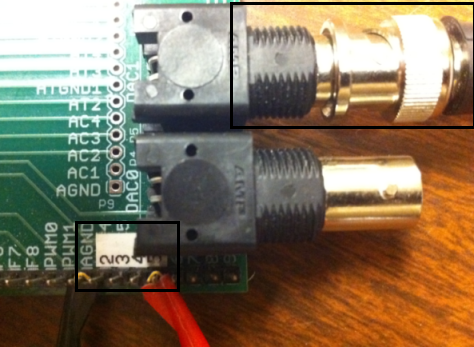

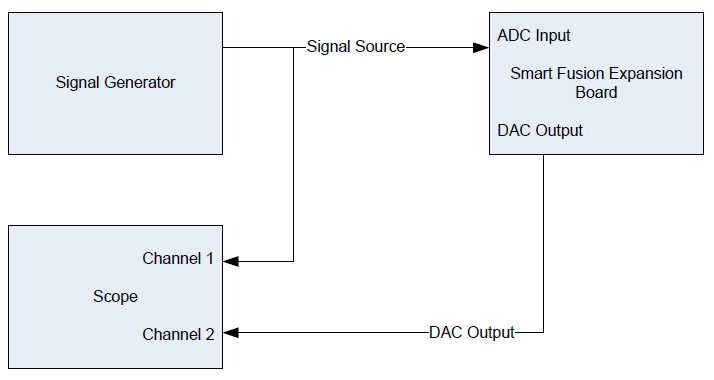

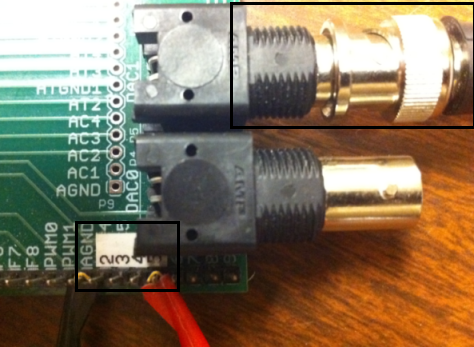

Connecting to the DAC and ADC

Hook the signal generator

to the extension board header pin 5 ( paper label) in the bottom right corner to provide

input to the ADC. If you don't have a paper label this is labeled ADC1.

Observe the DAC output on the 2nd BNC connector from the header pin.

Test ADC and DAC setup

Using the signal generator as a signal source, provide a sine wave that

centers a sine wave over the input range of the ADC (0 - 2.56 volts). A

DC offset of 1.25 volts should be fine with a Vpp (peak to peak)

voltage of 2.5 volts. Be sure the signal generator output is set to

High Z to insure accurate signal levels. Verify with the scope before

attaching to the kit to avoid damage to the ACE.

Aliasing Measurements

Slowly increase the frequency of the signal generator while observing

and measuring the frequency of DAC. Determine the frequencies or

frequency ranges for the following questions. You will need this

information to answer questions in the post lab.

- Over what frequency range is the reproduced signal frequency (DAC

output) and signal shape visually reproduced well?

- Over what frequency range is the reproduced signal frequency

intact, but the signal shape noticeably quantized?

- At what frequency is the reproduced signal frequency nearly zero?

- At what frequency is the reproduced signal frequency nearly half

the source?

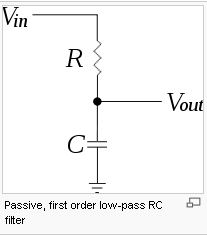

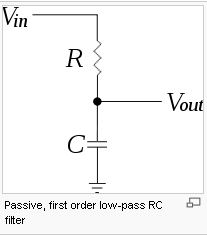

Implementing a Smoothing Filter

Quantizing in the DAC output can produce high frequency components that

in the audible range sound like common radio static. To remove these

components a low frequency pass filter can be used to reject the high

frequency components. We will use a simple passive filter consisting of

2 components.

To remove the high frequency components, consider

a half power point near the max frequency that you wish to pass. The

half power point or 3db down point (.707 volts below input voltage) is

give for a low pass filter to be 2pi f = 1/RC. Let's consider the case

for smoothing a 1 KHz signal. Choosing 2 KHz for the 3 db down point

gives 6.28 × 2000Hz × RC = 1. We must choose common RC

values. Starting with 1K ohm resistor gives a C of 0.08 UF (micro

farads or 10^-6 farads). The closest value in the lab is .068 uf. This

will produce a 3db frequency of ~2.34KHz. Close enough!

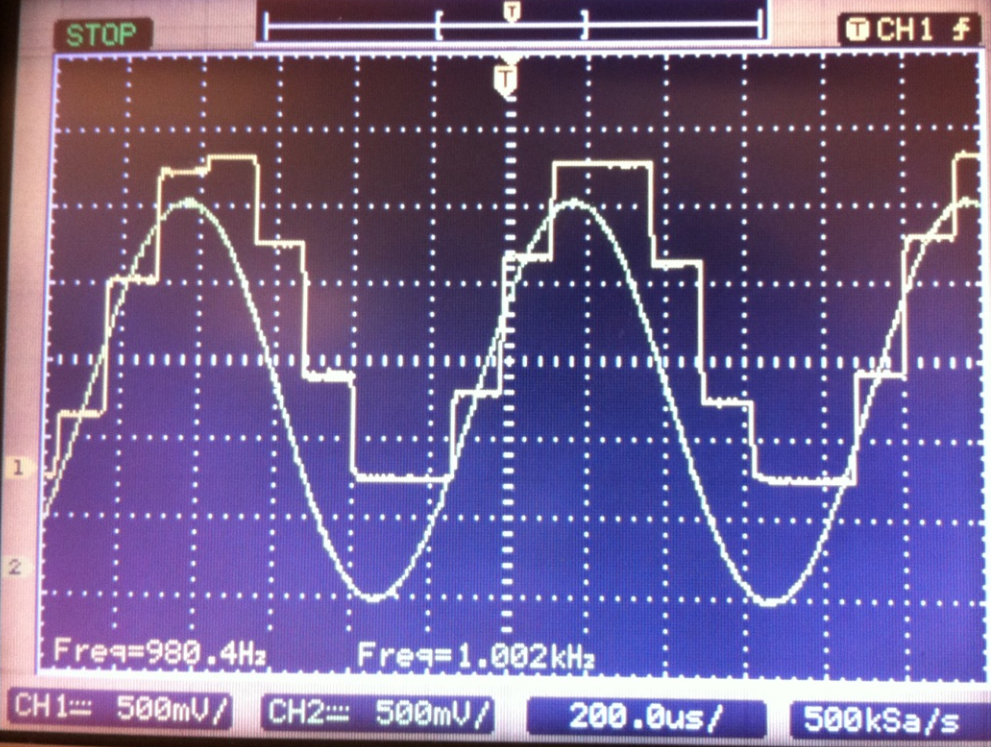

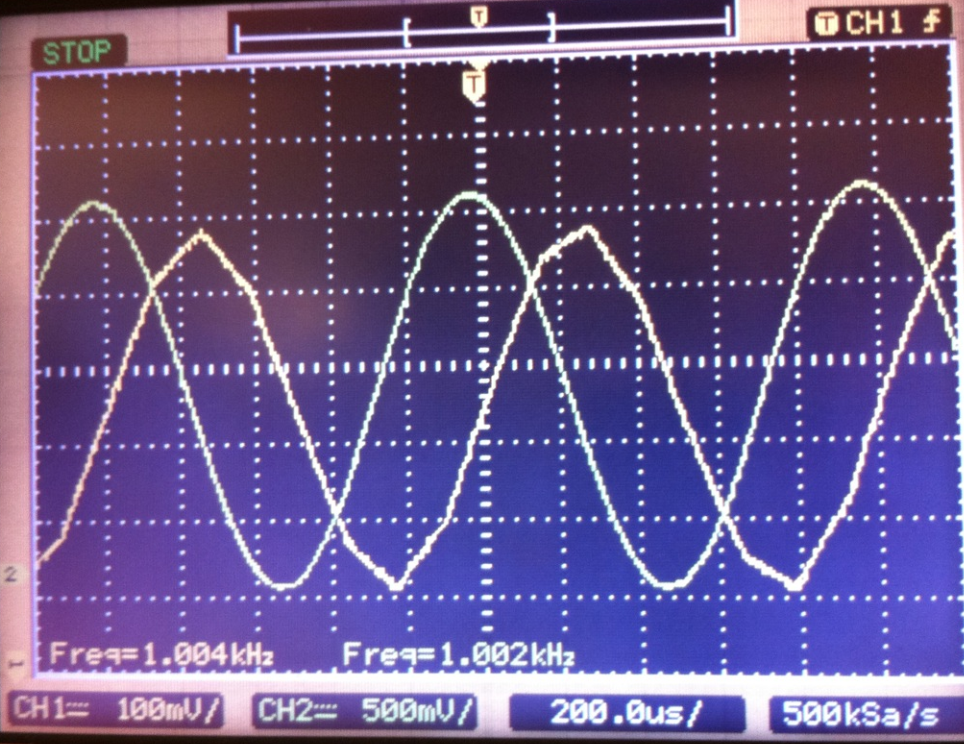

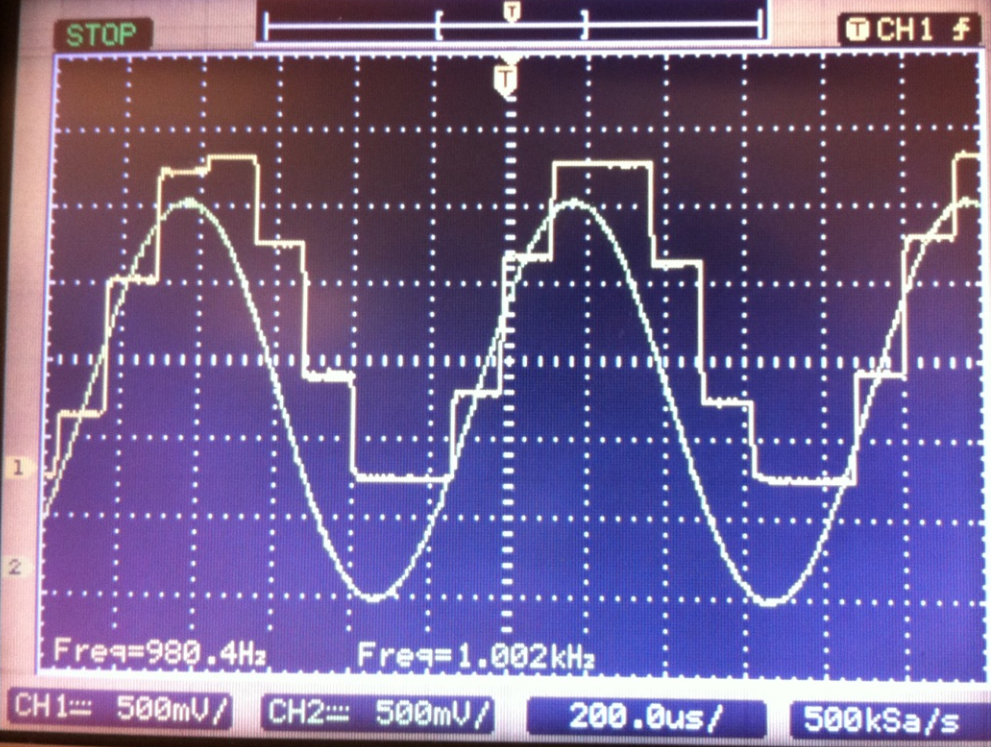

Set the source signal to 1 KHz sine wave. Observe the DAC output.

Notice the quantizing steps in the output wave form. With the input and

output waveforms displayed on the scope, it should look something like

this.

For the post lab, record the number

of quantizing steps there are per cycle.

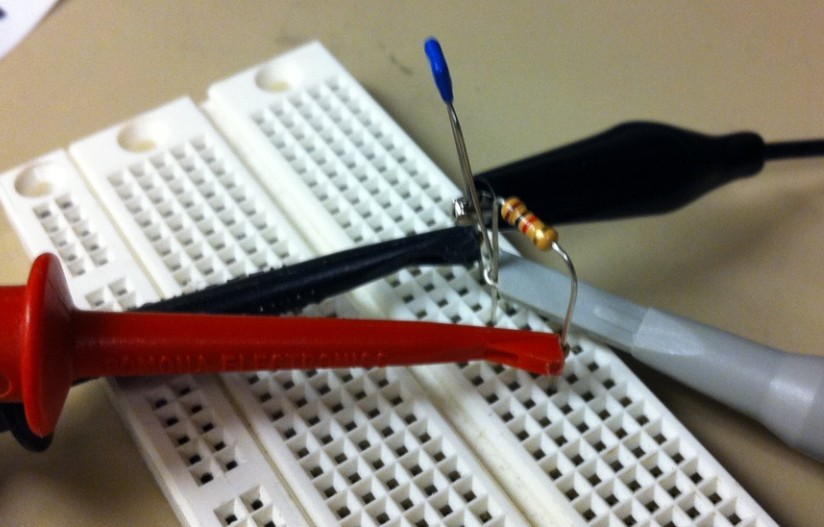

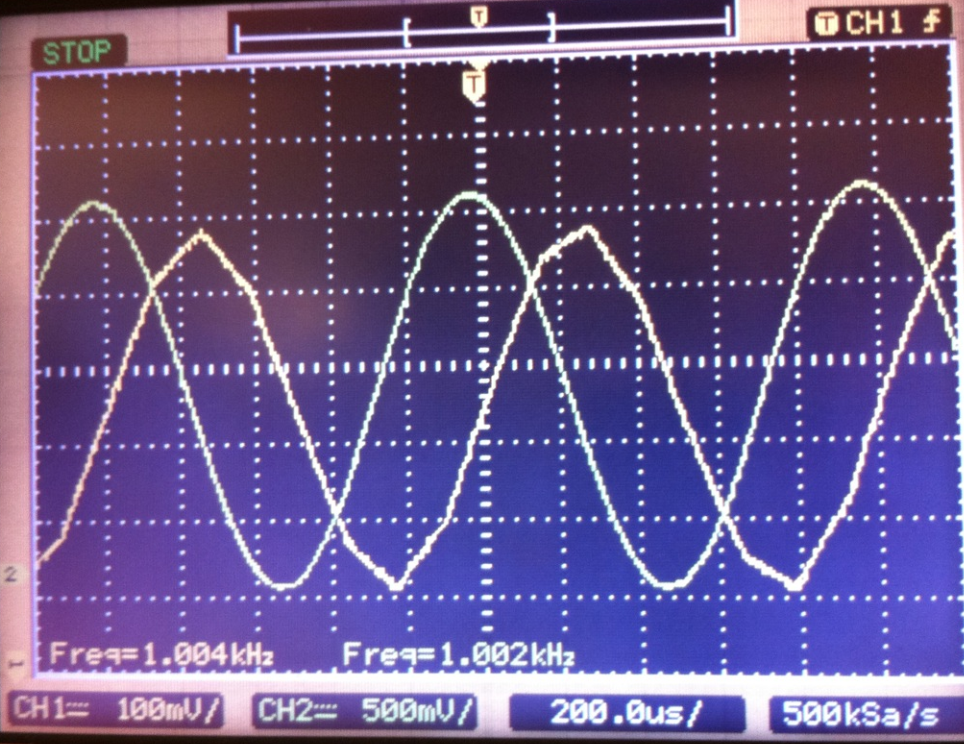

Construct a low pass filter with a 1K ohm resistor and 0.068uf

capacitor on a protoboard. Wire the DAC to the input of the filter and

observe the output.

You should notice a signal that is pretty close to a continuous sine

wave. The signal will be attenuated because of the filter.

The filter output amplitude should be about 0.707 the value of the

input voltage value at the 3db down frequency (2.34KHz) . Notice that

it is considerably lower. Adjust the frequency until the filter output

value is 0.707 the value of the source frequency and record the frequency for the post lab.

Measuring Quantization Error

In order to observe the ADC result correctly, we output the data

through screen instead of

using the scope. Adding the following line in the while(1) loop. Follow

lab 5 instructions to setup UART_0 for printf output.

printf("adc_result: %u\r\n", (adc_data>>4));

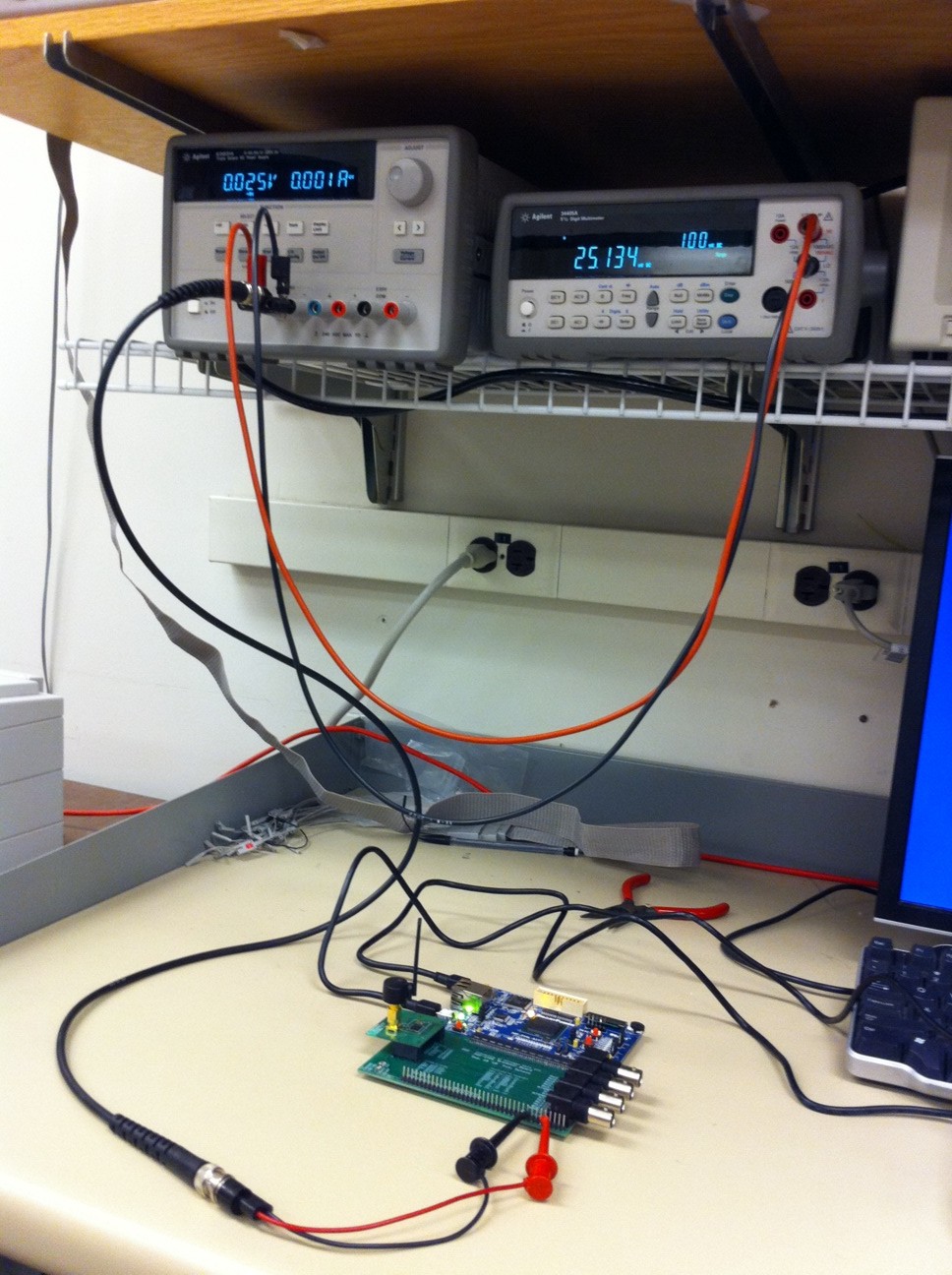

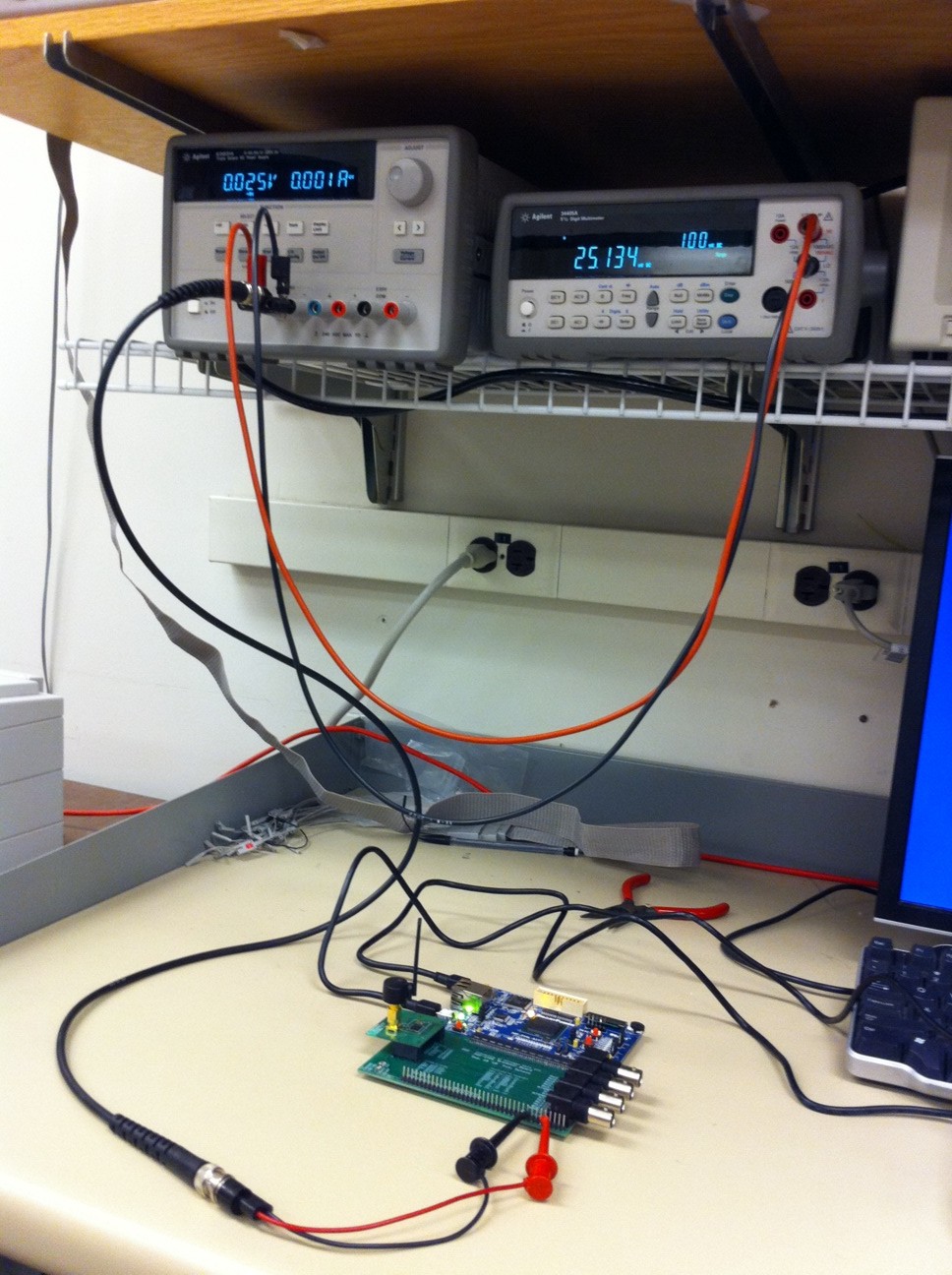

You will measure the transition or boundary voltages for the first 4

ADC conversion values 0, 1, 2 and 3. The lab power supply 0-6 volts

output can be adjusted to ~ 1mv, so you can use this as a voltage

source. The voltage meter on the power supply is not accurate enough

for 1 mv measurements, so you should use the DMM. Be sure to use the

cable configurations shown in the following configuration or you will

introduce interference that will make it difficult to resolve the

transition voltages.

TAKE CARE TO MATCH THE GROUND TAB

ON THE BANANA PLUG TO BNC ADAPTER TO THE GND PLUG OF THE POWER SUPPLY

OR YOU WILL SMOKE THE SMARTFUSION KIT!

The procedure for measuring the transitions voltages is to simply

start at 0 volts then gradually increase the voltage until you see the

conversion value change. The voltage at which the ADC conversion value

changes Is the transition voltage. You will find that the

transition voltage does not occur neatly on distinct boundaries. In

fact, it

will toggle between adjacent conversion values for several millivolts.

It will look something like this

Input Voltage (mv)

0-------4-------8--------------14-------18--------------24-------28--------------etc

Conversion Value

0,0,0,0-1,0-1,-1,1,1,1,1,1,1-2,1-2,1-2,2,2,2,2,2,2-3,2-3,2-3,3,3,3,3,3,

The conversion

uncertainty over the transition boundary is from signal variation

in the source voltage. In other words, it is an error source from the

measurement procedure. It is NOT from ADC quantizing. You can

assume the first voltage reading that is associated with an unstable

conversion value is the transistion volage for that interval. For

example, in the above example 0 to 4mv is the conversion interval for

0, 4mv to 14mv is the conversion interval for a value of 1, etc.

Mearsure the

conversion value as a function of the input voltage as shown above for

conversion values 0 through 3. Save these values for your post lab

report.

| Voltage

Range (mv) |

Conversion

Value |

|

0

<---> |

0 |

|

<---> |

0<-->1

unstable |

|

<---> |

1 |

|

<---> |

1<-->2

unstable |

|

<---> |

2 |

|

<---> |

2<-->3

unstable |

|

<---> |

3 |

|

<---> |

3<-->4

unstable |

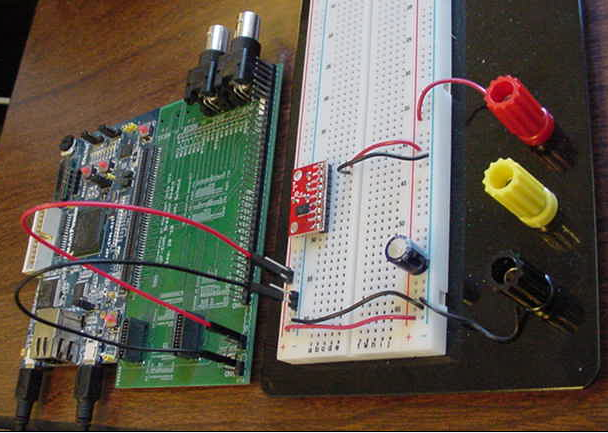

Reading Accelerometer Signals with ADC

For this part of the lab we will use the ACE, ADC to acquire the

signals of a typical device: the Freescale

MMA7361L triple axis accelerometer. This sensor is commonly

used in EECS 373 projects and represents a typical analog device

interfacing application.

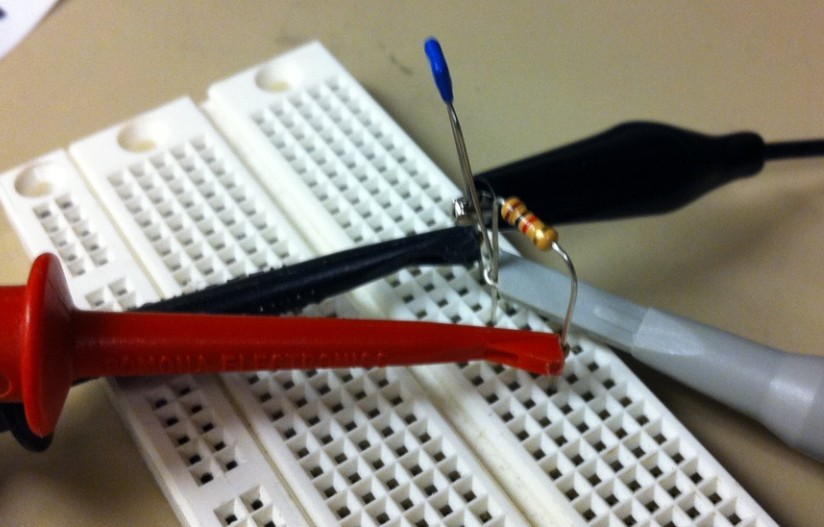

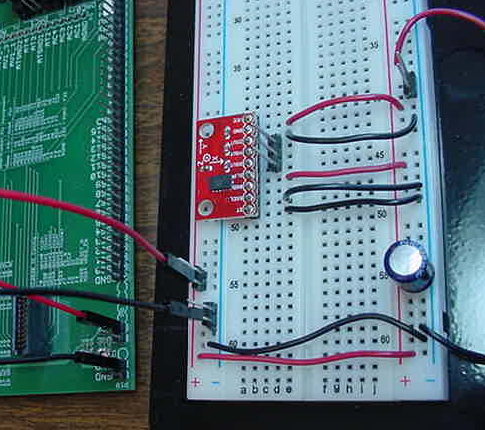

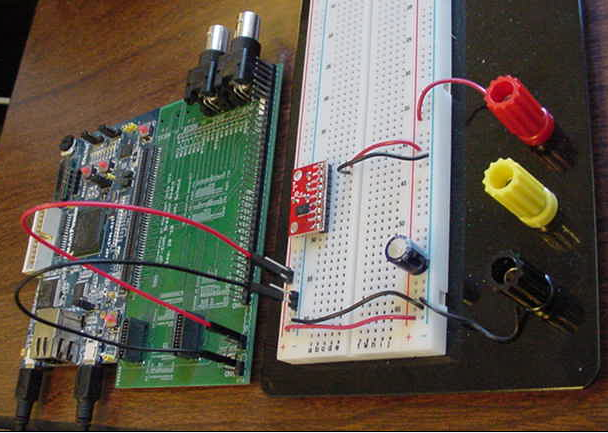

Breadboard the Accel

When testing or characterizing devices, it is convenient to use a

prototype board (protoboard) or breadboard. The board we will use is

the Sparkfun Breadboard.

For more information about protoboards see Wikipedia : BreadBoard.

In this case, we will provide power, control and output signal

connections between the protoboard and SmartFusion expansion card.

From the specification you will see the accelerometer is a surface

mount device. To make connections to this device, you will have to

solder little wires onto the pads or better yet use what is known as a

breakout pcb to facilitate the connections. You may have to do

something like this if you use such a component in your project.

Fortunately, Spark fun provides this component mounted to a PCB board

with convenient solder points connected to the device pins.

Here is the link Sparkfun

MMA7361L Kit . We have even soldered on a set of pins (a

header) so you can plug it into the protoboard.

The first order of business when breadboarding a device is to determine

the power connections and requirements. You will find in the

specification that the accelerometer requires 3.3 volts. It is

important not to exceed the maximum rating or apply the voltage in

reverse (negative voltage) or you will smoke the device.

Place the accelerometer in the protoboard as shown below. You may

have to rock the pins a bit to get it to go in the protoboard.

The power pins are labeled GND and VCC on the accelerometer

board. Rather then hook the power directly to these pins, jumper them

over to the power rails on the protoboard. Supply 3.3 volts to the

power rail from the expansion board or you can use a power supply. If

you use a power supply, use the banana plug terminals on the protoboard

to make the connection. You will also need to provide a GND connection

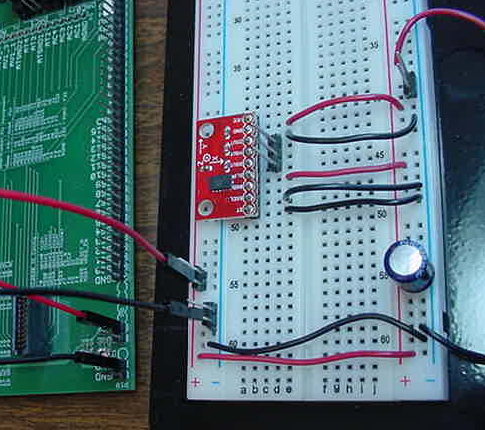

from the expansion board or power supply.

Notice that a decoupling capacitor is added across the power

rail. This is generally good practice when using a protoboard. Notice

also that a header pins are used to make some of the connections. These

are very handy when working with protoboards. They are available

in the lab in 40 pin lengths and can simply be broken to shorter

lengths as shown in the protoboard.

Next it is necessary to provide inputs to a few of the control signals

on the accelerometer. There is a self test control input labeled

ST and a gain select labeled GSEL that will need to be set to

GND. There is also a sleep mode that must be disabled by applying

VCC to the input. This pin is labeled SPL. The 0GD pin is an output

that will signal when 0 G is detected. In addition you should add some

header pins to the X, Y and Z outputs so you can easily attach a probe

or jumper. Additionally, put a jumper in the GND rail to conveniently

attach your scope probes.

Observing the Accelerometer Output with the Oscilloscope

When using devices for the first time, it is helpful to get a sense for

their performance by observing the behavior with standard lab

equipment. Lets try this with accelerometer by observing its behavior

with the oscilloscope. The accelerometers gain is set such that

the accelerometer will detect +/- 1.5 g maximum. You can use gravity as

your yardstick. Connect a scope probe ( a real scope probe, not grabber

clips) to the Y axis output. Make the following measurements. Save your

values for your post lab report.

When the protoboard is oriented flat on the desk, what value do you

read?

When you tilt the board to the right, what smallest value do you read?

When you tilt the board to the left , what largest value do you read?

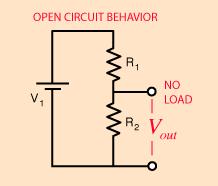

Voltage Scaling and Buffering

Scaling

The accelerometer will potentially produce a full scale voltage near

its supply voltage or 3.3 volts. You can observe this on the

Oscope by shaking the sensor exceeding +/- 1G. This can be a problem if

you want to observe sensor extremes on the ADC. The ADC can not measure

voltages exceeding its reference voltage of 2.56 volts. Voltages

exceeding 2.56 volts will be capped. If you want to measure

forces at this extreme you will have to scale the accelerometers

voltage

range of 0 - 3.3 volts to the ADC range of 0 - 2.56 volts.

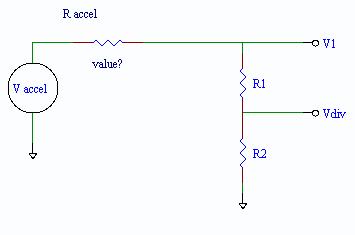

In this case we need to reduce the signal by the scaler 2.56 volts /

3.3 volts =

0.7758. Since we are reducing the signal, it is possible to reduce the

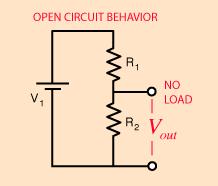

voltage with a simple voltage divider.

Where Vout is equal to Vin (R2 + (R1 + R2)). See this link

for more details. Using standard resistor values it is possible

to achieve the correct scaling with R1 = 2.7K and R2 = 10K. This will

result in a scaling multiplier of 0.7874. Close enough!!

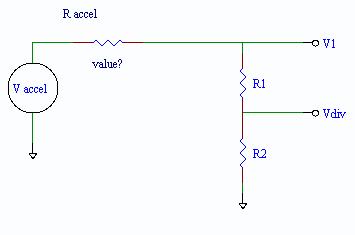

Loading From Source Voltage

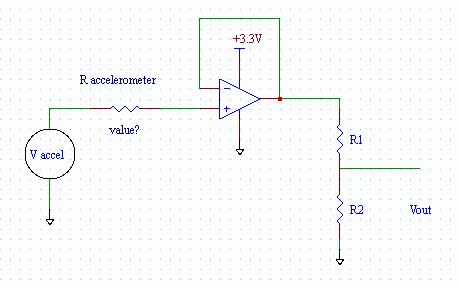

You will find that if you connect this circuit to the

accelerometer it will not scale as expected. This is because the

accelerometer output does not act like an ideal voltage source (no

source resistance). There is an output resistance that is in series

with the voltage source that will combine with R1 to change the voltage

divider ratio. The circuit is modeled like this.

Determine R accel.

Hint: Vaccel is can be determined by measuring the

open circuit voltage at V1 (R1 and R2 disconnected). Then measure V1

under the load of R1 and R2. Be sure to keep the

accelerometer stable during these measurements.

Provide your calculations and findings for the answer sheet in the Post Lab.

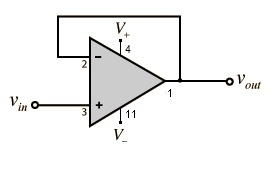

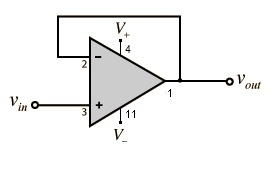

You can isolate the accelerometer from the divider

with a impedance buffer or more commonly known as a voltage follower.

The voltage follower has a very large input resistance and a very

small output resistance. As a consequence, it does not load the source

voltage and does not load the voltage divider. The voltage follower can

be implemented with an op amp as follows.

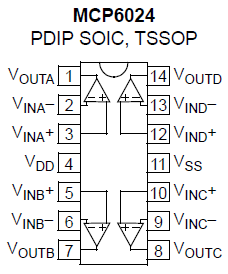

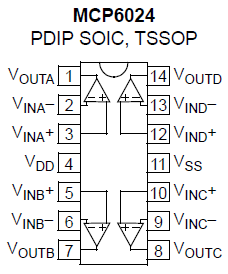

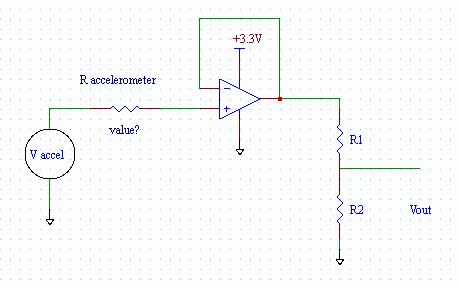

A very handy op amp for this purpose is the Microchip MCP6024

. It has 4 op amps in the same package and works well for our

voltage ranges. The following showes how to connect the buffer and

divider.

On your protoboard, wire the scaling circuits for all 3 accelerometer

axis using the op amp buffer. You can

supply the op amp chip with 3.3 volts from the expansion board. You can

check the output of the divider for correct scaling by using the

Oscope. Do not connect to the ADC yet.

Loading From the ADC Input Channel

The input resistance of the ADC can also act to load R2 of the

voltage divider. It manifests as a resistor in parallel with R2.

Therefore, if the load resistor is large, the effective parallel

combination of R2 and the load resistor will be R2 or it will not

effect the voltage divider. Fortunately, this is the case with our ADC

and there is not need to buffer or compensate the divider for loading

effects.

Note, before you can attach the

divider to the ADC input channels, you will have to program the ACE to

enable these channels (below) or you may observe loading effects.

Providing more ADC channels

You will have to add 2 more ADC channels for the post lab assignment.

To do this follow the procedure above adding 2 more ADC Direct

Input services in the ACE. You can provide any service name you

like, but the pin numbers must be specific to the kit. The following

screen shot shows all the possible ADC and DAC channels configured. The

service names are chosen to reflect the respective ADC channel. Note,

although ADC0 and ADC1 are shown in this configuration for

completeness, they are not connected to the SmartFusion kit with this

version of the expansion board. ADC2 through ADC7 are available.

Configure the ACE ADC for 3 inputs or services.

Remember to Generate in the MSS. This will add the additional hardware

and update the ADC drivers. You will have to copy the updated drivers

to your softconsole project.

The ADC channels are referenced in the ADC drivers with the Signal

names choosen in the ACE, ADC setup. For example, to add ADC channels 2

and 3 consider the following code.

#include <stdio.h>

#include <inttypes.h>

#include "drivers/mss_ace/mss_ace.h"

#include "drivers/mss_uart/mss_uart.h"

ace_channel_handle_t adc_handler2;

ace_channel_handle_t adc_handler3;

int main(){

ACE_init();

/* DAC initialization removed */

adc_handler2 = ACE_get_channel_handle((const uint8_t *)"ADCDirectInput_2");

adc_handler3 = ACE_get_channel_handle((const uint8_t *)"ADCDirectInput_3");

while(1){

uint16_t adc_data2 = ACE_get_ppe_sample(adc_handler2);

uint16_t adc_data3 = ACE_get_ppe_sample(adc_handler2);

}

return 0;

}

Post-Lab Assignment

Write an application program so that the LEDs mirror the accelerometer status.

That is, when the board is sitting flat the middle LEDs should be illuminated,

as the board is tilted, the LEDs should reflect the current board position:

LEDs: 00011000 10000000 0000001

/ \

BOARD: -------- / \

/ \

/ \

Selection through the 3 accelerometer axes with the push buttons. You can choose

the switch combinations and it is OK if you have to hold the switch to maintain

the selection. Consider using the builtin MSS GPIO module to provide your LED

and switch hardware interface (this will involved opening the MSS configurator,

configuring the GPIO block to route GPIOs through the "Fabric" (FPGA), and then

mapping the GPIOs to the LEDs and switches).

Post-Lab Questions

The post lab questions can be found on this answer sheet. Use this form

to submit your answers or copy into to a word processing program.

,

and configure it to 115us. Move the Wait

for 115.00us above Restarts the execution sequence for this

timeslot. Click Calculate Actual Rate.

The Actual Rate for ADC / DAC should be 8.000 ksps.

,

and configure it to 115us. Move the Wait

for 115.00us above Restarts the execution sequence for this

timeslot. Click Calculate Actual Rate.

The Actual Rate for ADC / DAC should be 8.000 ksps.