EECS 373 Lab 3: Introduction

to Memory Mapped IO

Copyright © 2010-2011,

Matt Smith,

Thomas Schmid,

Ye-Sheng Kuo,

Lohit Yerva,

and Prabal Dutta.

9/27/2011v4

Schedule

See posted lab schedule for due dates, in-lab, and post-lab due dates.

Objectives

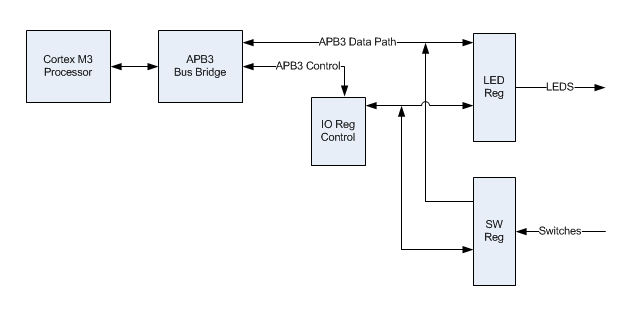

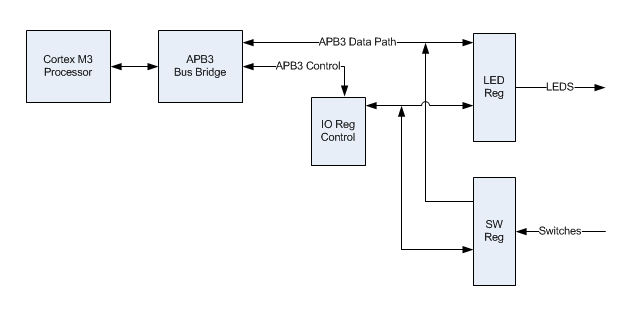

In Lab 2 we provided you with the "hardware" to read and write the LEDs

and switches from software. We used dedicated hardware that

Actel provides for this purpose. In this lab we will discover how to

create our own hardware in the FPGA for this purpose. You will provide

the memory locations (registers), data path and control to access

registers connected to the LEDs and switches.

Overview

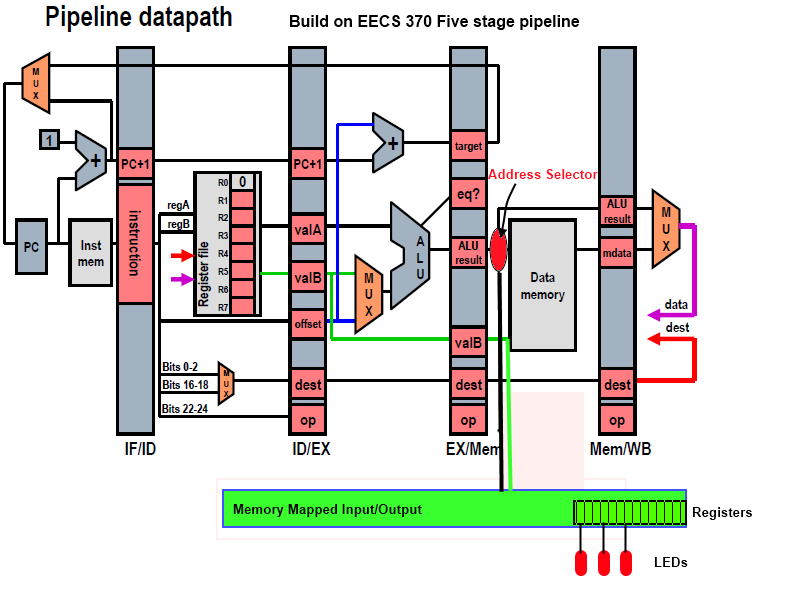

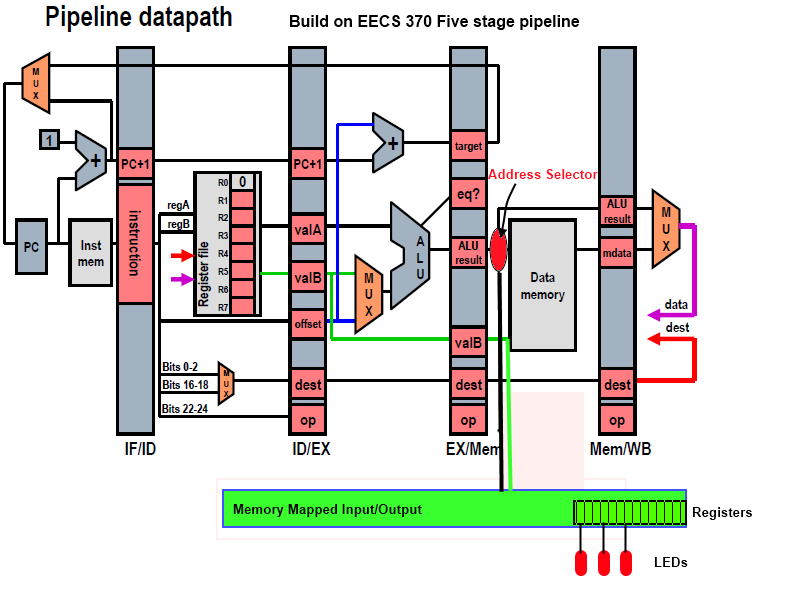

Remember the EECS 370 five stage pipeline? The only thing it could do

was read and write from memory. In EECS 270, you built a D-Flip-Flop

from gates and understood how to read and write from it. A DFF is also

called register, which is physically the same at the registers in the

processor. In the EECS 270 lab, you connected an LED to the output of a

DFF or register. How does a processor control an LED? By writing values

to the LED register. We use a method called Memory Mapped I/O to allow

the processor to access the LED register. Basically, some region of the

memory address space is allocated for the external I/O devices. The

value that the processor thinks is sending to some location in standard

memory is physically redirected to a an array of registers.

Pre-Lab Assignment

There is no Pre-Lab assignment for this lab. Read over the In-Lab

assignment and get started.

In-Lab Assignment

The In-Lab assignment is a tutorial that shows you how to interface to

the LEDs and push button

switches as memory mapped IO (MMIO), that is we will read and write the

LEDs and switches as though they are memory locations. The functional

components of the MMIO interface are organized a bit like this.

We will implement the register

control, registers, connections to

the LEDS and switches in Verilog.

We will use some prepackaged "core" from Actel and the Libero Smart

Design environment to make the bus connections.

1 Creating the IO

Registers

We will create registers in the FPGA that will act as the storage

element for the memory mapped IO

interface. Lets start with LED register. The register will be 8 bit,

read/write with the output ported directly to the LEDS. A reset is

provided that sets the register to logical 0. We have provided you with

the following example code to do this. Create a new project, create a

new Verilog file as you did in lab one and copy the the following

contents into it. Save the file. Do a HDL check to be sure all is well.

// ledreg.v

module ledreg( clk, nreset, wr_en, rd_en, data_in, data_out, led_port);

//Inputs Declarations

input clk; //Clock

input nreset; //active low reset

input wr_en; //Write Enable

input rd_en; //Read Enable

input [7:0] data_in; //Data Input

//output Declarations

output [7:0] data_out; //Data Output

output [7:0] led_port; //path to led connection

//reg Declarations

reg [7:0] ledioreg; //the io register

reg [7:0] data_out; //Data Output

wire [7:0] led_port;

//map led register to leds

assign led_port = ledioreg;

//read led register

always @(posedge clk, negedge nreset)

begin : READ_GEN

if(nreset == 1'b0)

begin

data_out <= 8'h00;

end

else if(rd_en)

begin

data_out <= ledioreg;

end end

//write led register

always @(posedge clk, negedge nreset)

begin : WRITE_GEN

if(nreset == 1'b0)

begin

ledioreg <= 8'h00;

end

else if(wr_en)

begin

ledioreg <= data_in;

end

end

endmodule

Next lets create a register for the switches. Although we only need 2

bits for the switches, we will create an 8 bit register, make it read

only with a direct input connection from the switches. We have provided

you with the following example code to do this. Create a new Verilog

file as you did in lab one and copy the the following contents into it.

Save the file. Do a HDL check to be sure all is well.

// swreg.v

module swreg( clk, nreset, rd_en, sw_port, data_out);

//Inputs Declarations

input clk; //Clock

input nreset; //active low reset

input rd_en; //Read Enable

input [1:0] sw_port; //path from switches

//output Declarations

output [7:0] data_out;

//reg Declarations

reg [7:0] data_out;

wire [1:0] sw_port;

//read led register

always @(posedge clk, negedge nreset)

begin : READ_GEN

if(nreset == 1'b0)

begin

data_out <= 8'h00;

end

else if(rd_en)

begin

data_out[0] <= sw_port[0];

data_out[1] <= sw_port[1];

end

end

endmodule

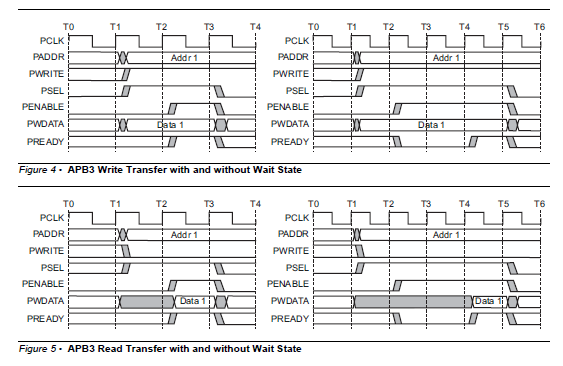

2 Creating and APB3

"wrapper"

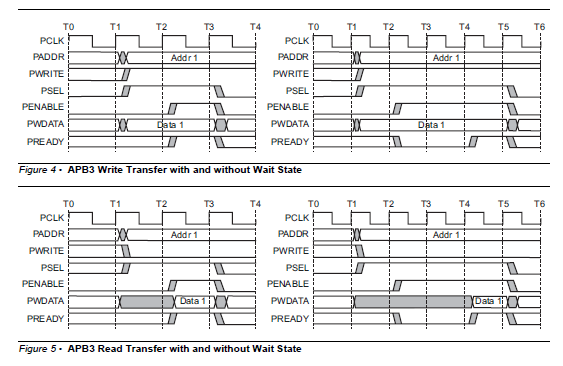

The name wrapper is a bit of misnomer: it is really an interface.

Specifically, it is the Verilog that provides the interface interface

between your IO register and the APB3 bus. The wrapper provides a

control and data path conections and control logic between the IO

register and the Cortex M3 APB3 bus. The APB3 bus (advanced peripheral

bus) is designed to interface with slow IO and has a simple protocol.

Transfers fundamentally consists of two cycles: the setup phase and

access phase. During the setup phase, the processor provides unique

information that identifies the transaction such as read/write, device

address, etc. During the access phase, the device either provides or

excepts data from the processor. Additionally, the device provides a

control signal during the access phase to the processor to extend the

phase if more time is needed to latch or provide data. For more detail,

you can see the reference at the end of the lab. For your convenience,

the read/write transfer cycles with and without extended accesses are

provide below. A description of the signals follows.

A

quick summary of the APB3 signals:

A

quick summary of the APB3 signals:

PCLK: The

bus clock. All transfers are synchronized to this clock.

PSEL:

A signal provided by the APB3 bus interface that is used to

uniquely select the device over

some predefined address range.

PADDR:

Used to address within the predefined address range.

PWRITE:

Determines if it is a read

(low) or write cycle (high).

PENABLE:

Identifies the access phase.

PREADY:

Signal used by peripheral to extend access phase. Low extends

the cycle, high releases the cycle.

PWDATA

and PRDATA: Write and read

data buses.

PSLVERR:

Use by the peripheral to indicate a transfer error.

How

can we use these transactions to read and write our IO registers?

- Consider the case of writing

the LED register. Examining the verilog

code we see that the register is written on the rising edge of clk and

wr_en true. To generate wr_en signal, the device has to be selected

(PSEL == 1), it has to be a write cycle (PWRITE == 1) and it should be

an access phase (PENABLE == 1).

- So

we have wr_en = PSEL && PWRITE &&

PENABLE with the

PCLK used as the register clock.

The read register is similarly accessed except PWRITE == 0 and the

processor requires that the data

is available at the beginning of the access cycle so PENABLE is

omitted.

- So we have wr_en = PSEL &&

!PWRITE with the PCLK used

as the

register clock.

- There is no need to extend the access

cycle, so PREADY is set logical

1. There is no criteria for PSLVERR so it is driven logical 0.

The following code is working Verilog

APB3 wrappers for the LED and

switch registers. Notice that these wrappers port some the APB3 signals

to the user IO so we can observe them. Create Verilog files, copy this

code and verify with the HDL checker.

// ledregwrp.v

module ledregwrp(

PCLK,

PENABLE,

PSEL,

PRESERN,

PWRITE,

PREADY,

PSLVERR,

PWDATA,

PRDATA,

LEDCON,

TPS);

input PCLK,PENABLE, PSEL, PRESERN, PWRITE;

input [7:0] PWDATA;

output [7:0] PRDATA, LEDCON;

output PREADY, PSLVERR;

output [4:0] TPS;//test points

wire rd_enable;

wire wr_enable;

assign wr_enable = (PENABLE && PWRITE && PSEL);

assign rd_enable = (!PWRITE && PSEL); //Data is ready during first cycle to make it availble on the bus when PENABLE is asserted

ledreg ledreg_0 (.clk(PCLK), .nreset(PRESERN), .wr_en(wr_enable),

.rd_en(rd_enable), .data_in(PWDATA), .data_out(PRDATA), .led_port(LEDCON));

assign PREADY = 1'b1;

assign PSLVERR = 1'b0;

assign TPS[0] = PCLK;

assign TPS[1] = PWRITE;

assign TPS[2] = PSEL;

assign TPS[3] = PENABLE;

assign TPS[4] = PREADY;

endmodule

// swregwrp.v

module swregwrp(

PCLK,

PENABLE,

PSEL,

PRESERN,

PWRITE,

PREADY,

PSLVERR,

PWDATA,

PRDATA,

SWCON,

TPS);

input PCLK,PENABLE, PSEL, PRESERN, PWRITE;

input [7:0] PWDATA;

input [1:0] SWCON;

output [7:0] PRDATA;

output PREADY, PSLVERR;

output [4:0] TPS;//test points

wire rd_enable;

wire wr_enable;

assign rd_enable = (!PWRITE && PSEL); //Data is ready during first cycle to make it availble on the bus when PENABLE is asserted

swreg swreg_0 (.clk(PCLK), .nreset(PRESERN),

.rd_en(rd_enable), .data_out(PRDATA), .sw_port(SWCON));

assign PREADY = 1'b1;

assign PSLVERR = 1'b0;

assign TPS[0] = PCLK;

assign TPS[1] = PWRITE;

assign TPS[2] = PSEL;

assign TPS[3] = PENABLE;

assign TPS[4] = PREADY;

endmodule

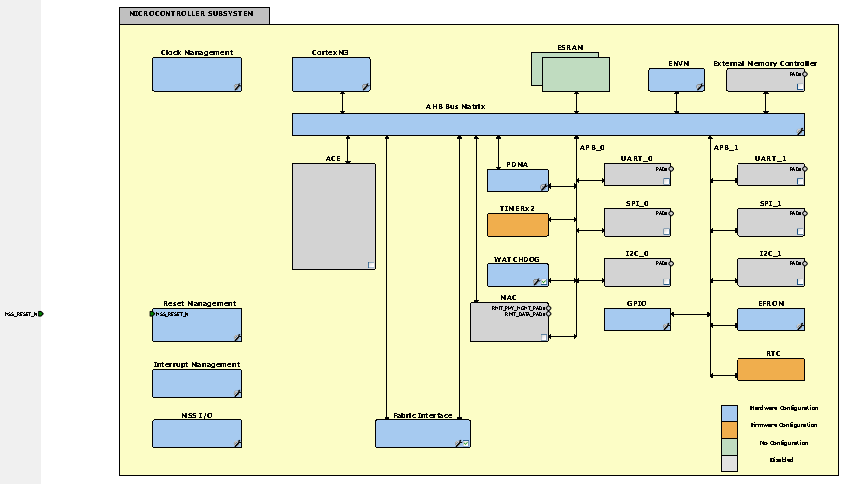

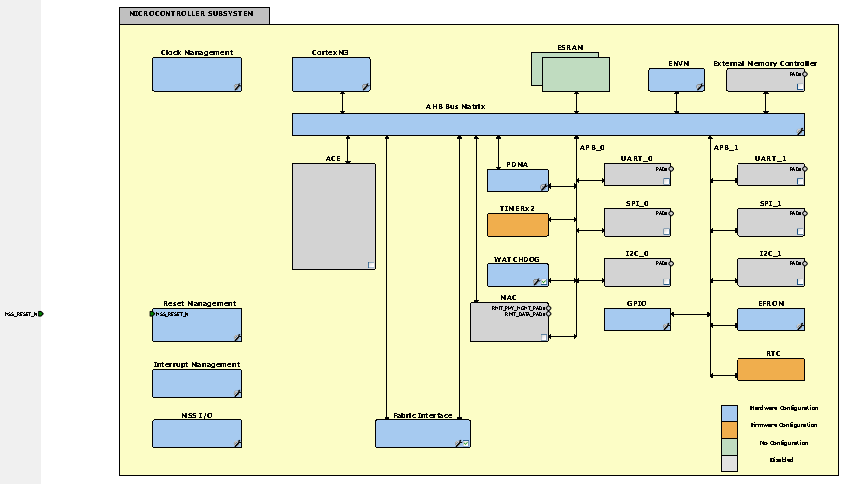

3 Provide

Microcontroller Subsystem Components

To complete the connection between the IO

registers and APB3 bus, we

will need access to the system power up reset, a clock for the bus and

connections to the APB3 data and control path. Access to these

connections is provided thru the SmartFusion MSS (Microcontroller

Subsystem). Many standard microcontroller subsystem components are

provided including general purpose timers, serial IO interfaces, memory

controllers, etc. These components are configured under the MSS

(Microcontroller Subsystem) icon.

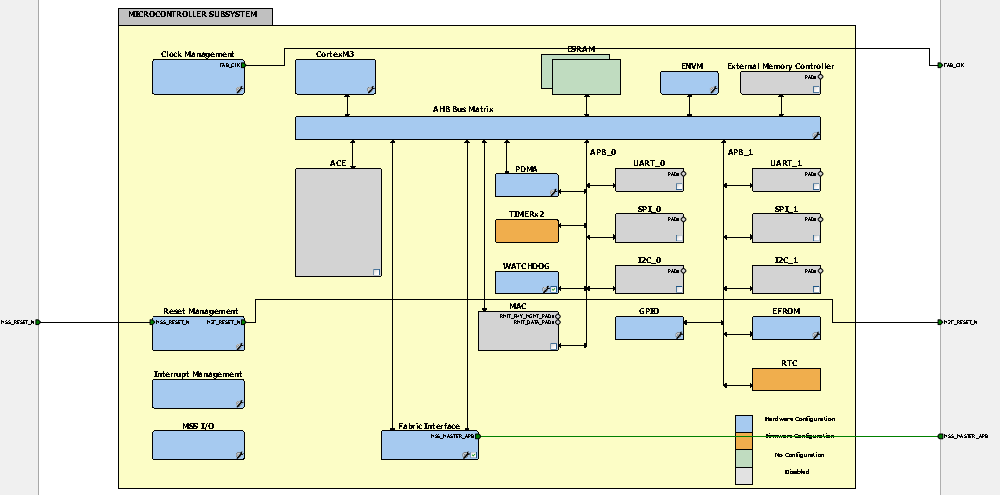

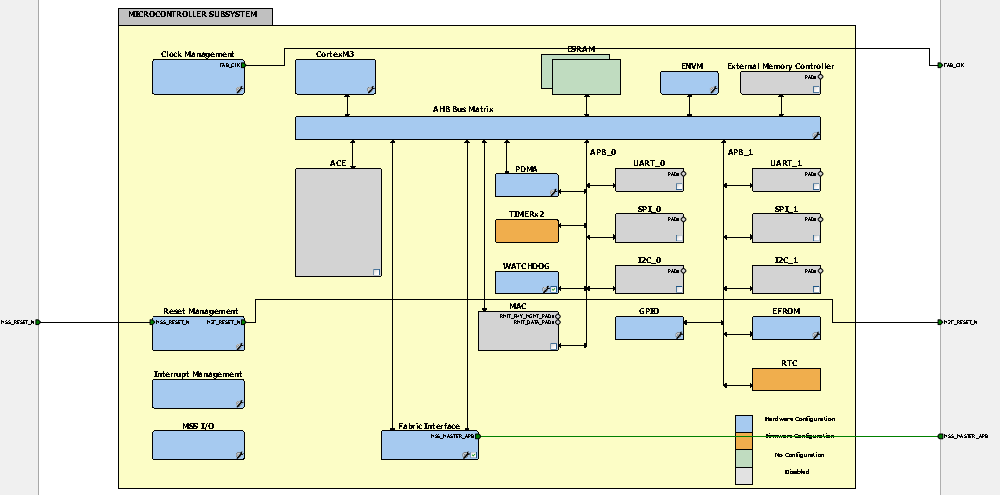

3.1

Enable Relevant MMS

Components

Double click on the MSS icon in the

project flow window and provide a

name to the MSS configure such as m. A view of the MSS system

will open revealing all the available components and connections. All

the components are enabled to begin. We will only need the Reset

Management, Fabric Interface< Watch Dog and Clock Management

Component. The components are enabled by selecting the check box in the

lower right corner. Notice that some components like the Clock

Management do not have the option to exclude since they are needed for

any configuration. Turn off all the components we don't need and your

canvas should look something like this.

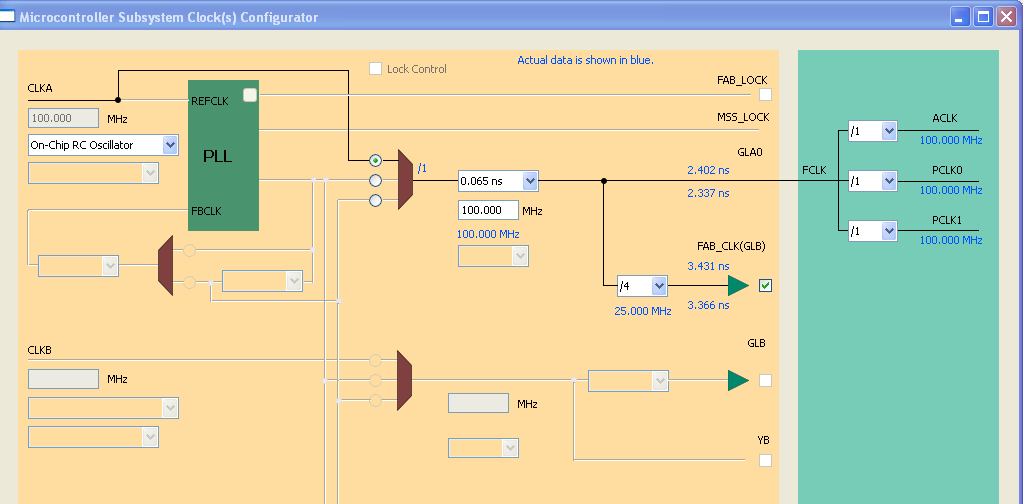

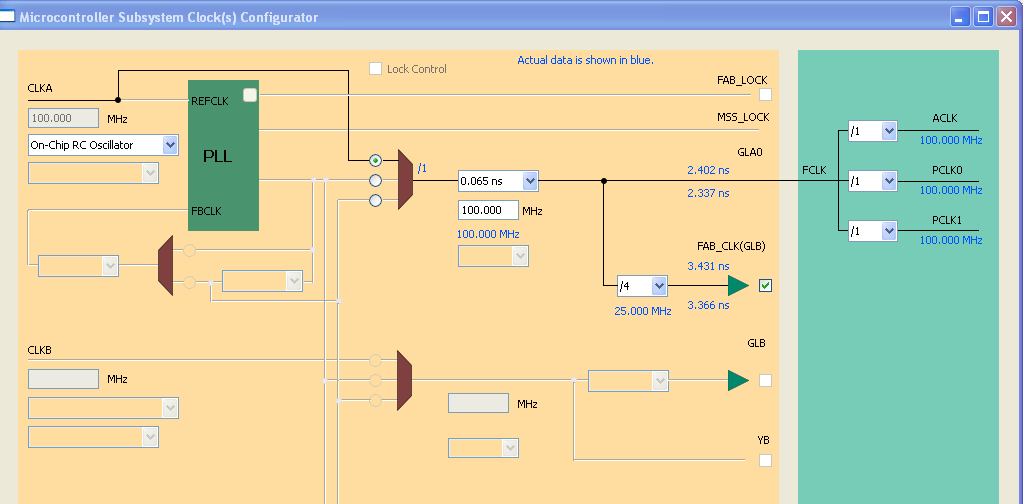

3.2

Configure Clock

Manager

This component provides clock sources for

the various system components

and custom FPGA hardware. We will use a clock that can be mapped to the

FPGA hardware for the APB3 bus clock. Double click on the Clock

Management icon. FAB_CLK (fabric clock) is the FPGA clock. Enable by

clicking on the box. We are going to divide the clock down from the

source clock (100 MHz) to 25 MHz. Do this by selecting the drop down

menu just upstream from the FAB_CLK output and select divide by 4. The

default source clock should be the RC oscillator (upper left). Also,

you should notice the FAB_CLK added as an output port (upper right)

from the MSS system to the FGPA fabric when you return to the MSS

canvas. The connections are not shown between the components and MSS

boundary. You can add them under the Canvas menu if you wish (show

nets). The clock manager configuration should look something like this

before closing.

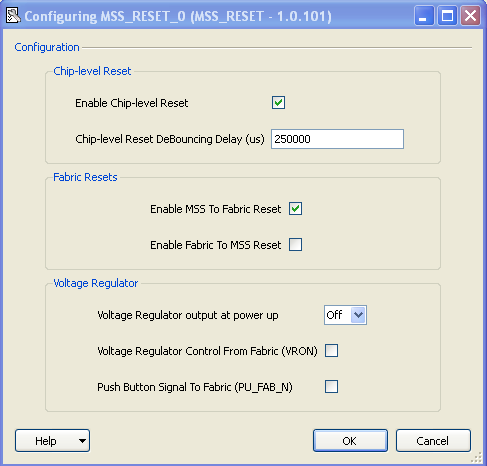

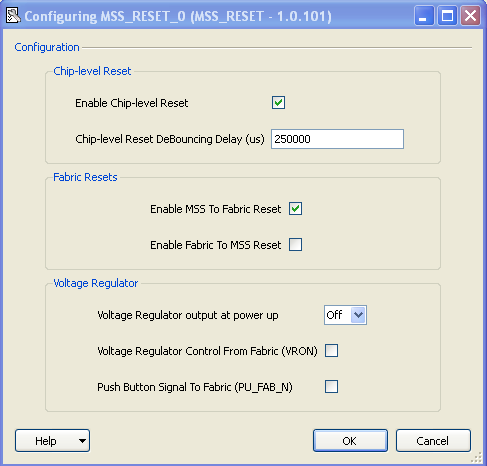

3.3

Configure Reset

Manager

The reset manager provides power up

system reset to the various

components and FPGA fabric. We need provide the power up reset to the

FPGA fabric. Open the Reset Manager and select "Enable MSS to Fabric

Reset". It should look like this and you should notice a reset output

to the FPGA fabric on the MSS canvas.

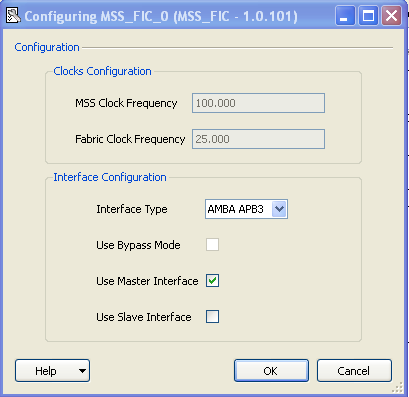

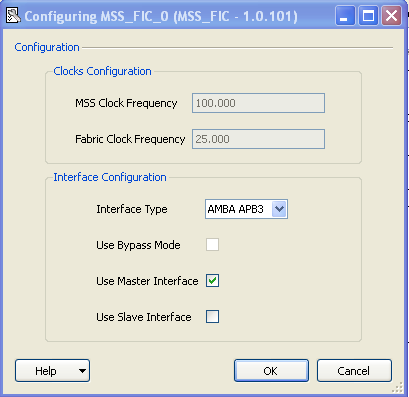

3.4

Configure Fabric

Interface

The Fabric Interface component is use

configure bus ports to custom

FPGA hardware. In this case we must configure a APB3 interface. Double

click on the icon opening the fabric interface configuration. Notice

that the MSS clock frequency and fabric clock frequency are inherited

from the clock settings. We need a APB3 interface so select "AMBA

APB3". The interface will act as a "Master" controlling the LED and

switch registers so configure as MSS Master. The setting should look

like this.

3.5

Generate MSS

Finally HDL has to be generated from the

MSS for synthesis. Click the

generate icon or select under the design menu. Make sure there are no

errors indicated in the script below. The MSS generator will warn you

that a root has not been set for the design hierarchy. You can ignore

this for now. The final canvas should look something like this with the

net view enabled (not necessary). Inspect the project explorer in the

files tab and you will see Verilog files added for the MSS components.

4 Connecting the IO

Register Wrappers to the APB3

Libro provides a graphical editor for making system component

connections between MSS components, custom logic and other high level

core. We will use this tool to make our connection between the IO

register wrappers and the Cortex M3 APB3 bus. Open SmartDesign (click

on the ICON in Project Flow), select SmartDesign Component, choose a

descriptive name such as apb3_to_ledswreg. A canvas should open without

any components.

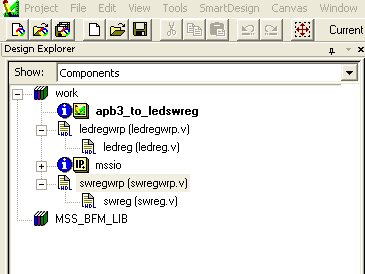

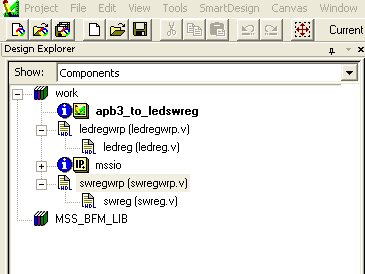

4.1

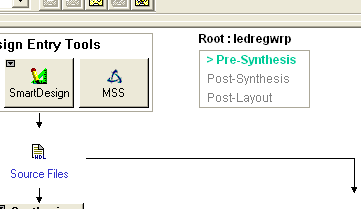

Set Design Hierarchy

Root

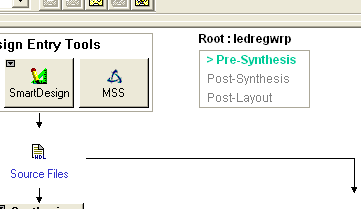

Select the Hierarchy tab in the Design Explorer, select the

apb3_to_ledswreg, right click and set as the root. This sets the

apb3_to_ledswreg as the top level in the design hierarchy. The file

hierarchy should look something like this. Notice IP from the MSS

configuration and the verilog files we provided earlier.

Notice that in the design flow apb3_to_ledswreg is set as the

root in

the upper right corner.

Notice that in the design flow apb3_to_ledswreg is set as the

root in

the upper right corner.

4.2

Instantiate MSS

Components in SmartDesign Canvas

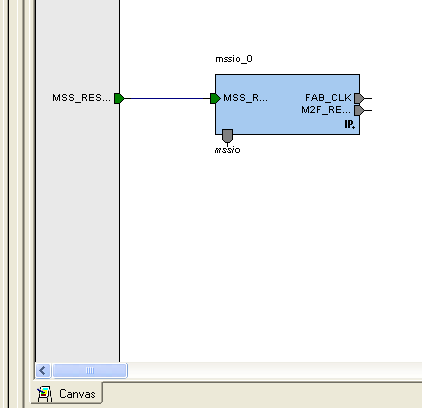

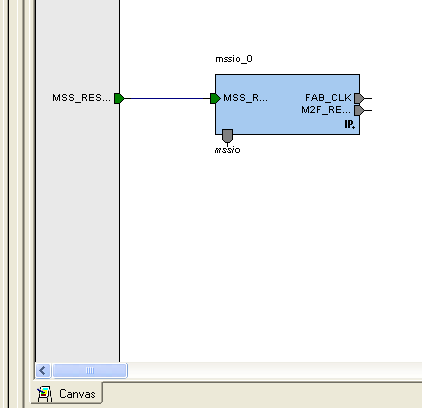

We need to start by instantiating the MSS

components we establishes

earlier in the SmartDesign Canvas. Select IP mssio in the Design

Explorer and drag it into the SmartDesign canvas. Or, select IP mssio,

right click and choose instantiate in apb3_to_ledswreg. The MSS

components we configured will be represented as a block with the ports

we provided. The reset connection is automatically made since this is a

fixed input. The block should look something like this.

4.3

Instantiate

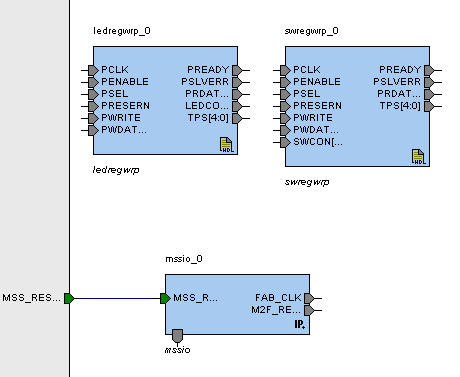

Register APB3 Wrappers in SmartDesign Canvas

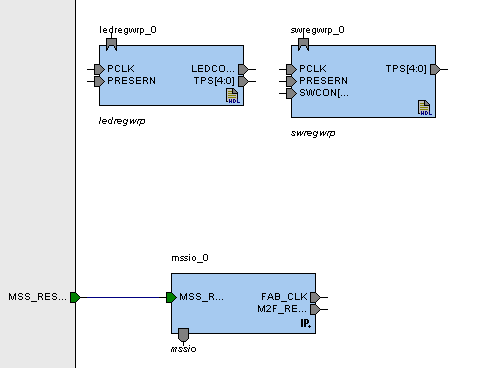

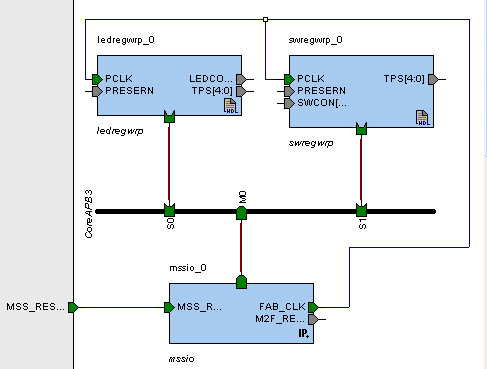

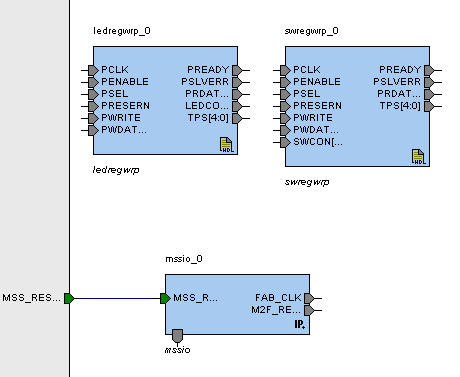

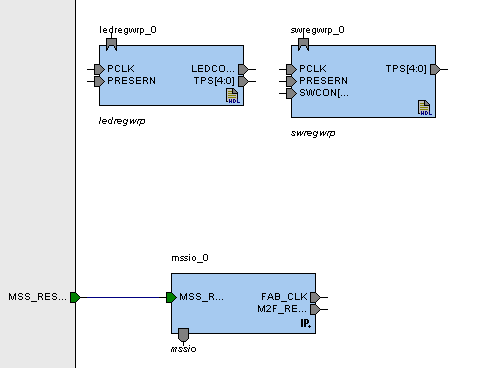

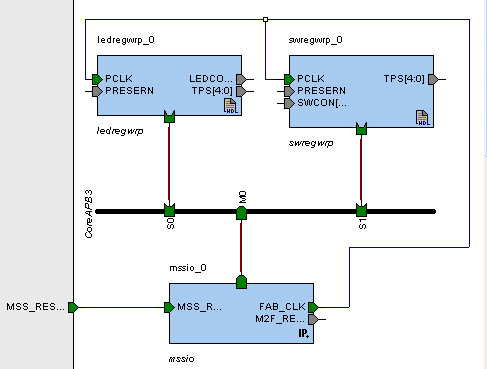

Again, select the ledregwrp and swregwrp and drag onto the

canvas. The

blocks will be instantiated and look a bit like this.

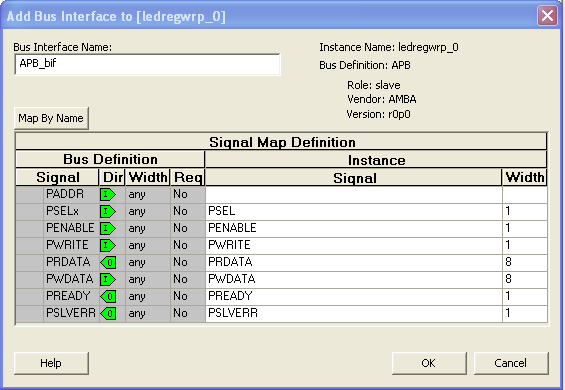

4.4

Convert IO Register

APB3 Wrapper Ports to APB3 Slave

Interface

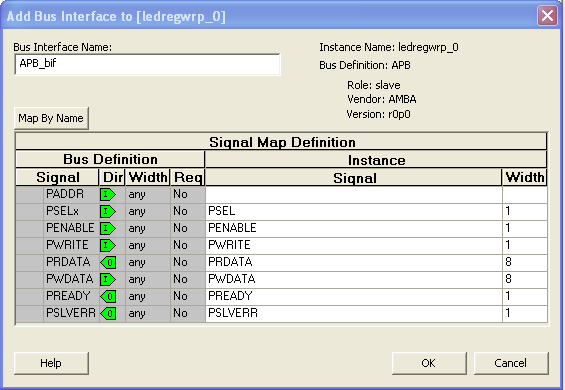

Next we need to repackage the

wrapper ports so that they interface a

bit easier with standard APB3 signals. SmartDesign has a handy tool for

this. Select the Bus Definitions tab (lower right) in the Catalog

window (right). Select APB, AMBA, AMBA2, slave. Drag this onto one of

the instantiation blocks of one of the wrappers. You will be prompted

to associate the signals of the wrapper with standard APB3 signals.

Many of these can be associated automatically by using the map by name

feature (upper right) if we took care to use similar names when we

created the wrapper ports. You will find most of these signals mapped

except PSELx and PADDR. Use the signal window set PSELx to PSEL and the

width window to set to 1 bit. We are not using PADDR so it can remain

blank. The result should look like this.

Repeat the process for the other wrapper. The blocks should now

look

like this. Notice that all the APB3 signals are contained in one bus

connection.

Repeat the process for the other wrapper. The blocks should now

look

like this. Notice that all the APB3 signals are contained in one bus

connection.

4.5

Instantiate APB3

Core Interface

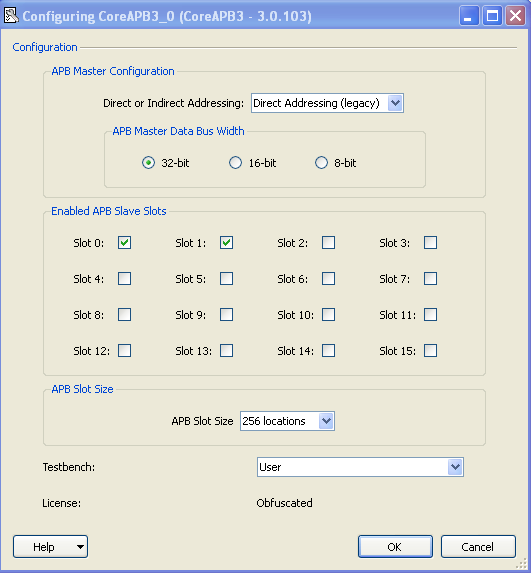

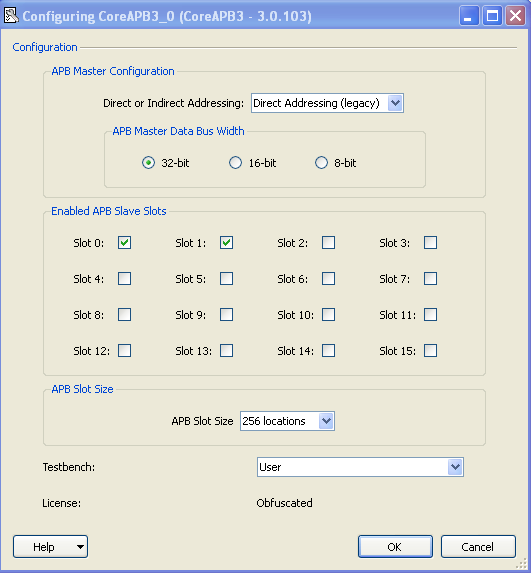

Under bus interfaces in the catalog

window (left) select CoreAPB3 and

drag onto the canvas. A configuration window will appear. Basically

allows you to determine how many IO devices you wish to select and how

much memory space you wish to allocate per device. Keep all the

settings but reduce the slot number (devices) to just two. It should

look like this.

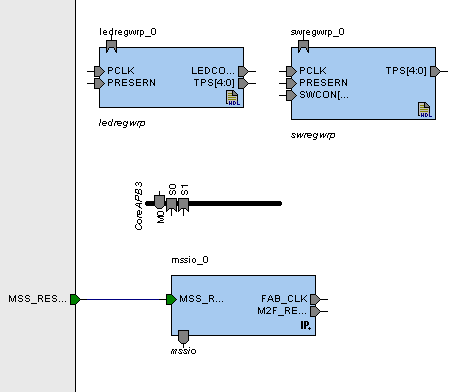

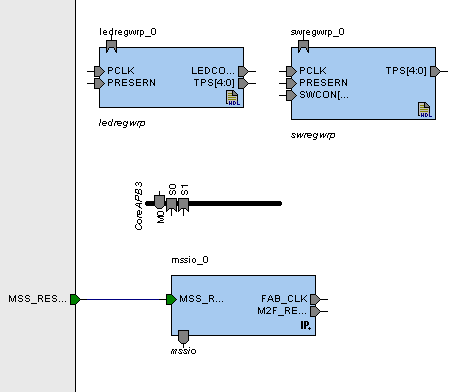

Acknowledge this window and a APB3 bus connection icon will

appear in

the canvas. You may want to position it and size it. The canvas should

look like this now.

Acknowledge this window and a APB3 bus connection icon will

appear in

the canvas. You may want to position it and size it. The canvas should

look like this now.

4.6

Connect IO Register

APB3 Wrappers to APB3 Core Interface

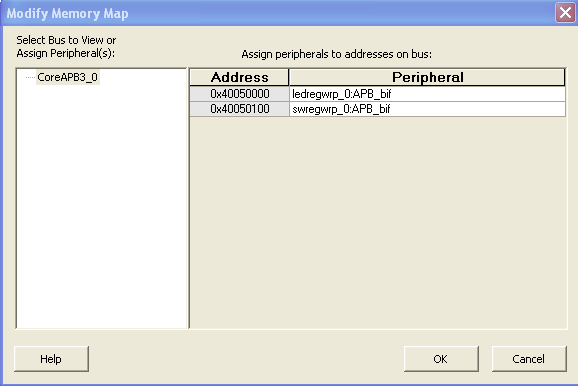

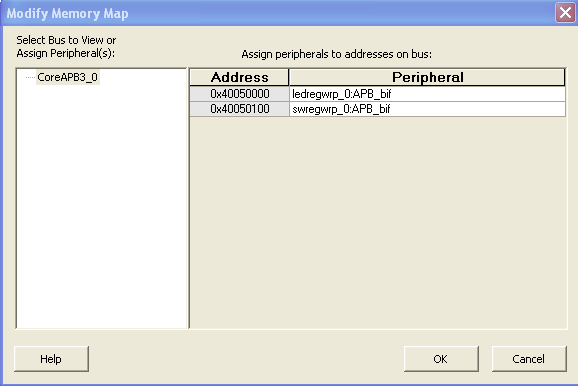

Finally, we can connect the components. SmartDesign has a handy

tool

for this to. Right click on the canvas and select auto connect. A

window will appear asking you to acknowledge the addresses SmartDesign

is assigning to the 2 registers. Notice that each address has an

address range of 256 bytes as set in the configurator earlier. Agree to

these addresses. The window looks a bit like this.

After acknowledging the memory locations the APB3 connections

will be

made and look a bit like this.

After acknowledging the memory locations the APB3 connections

will be

made and look a bit like this.

4.7

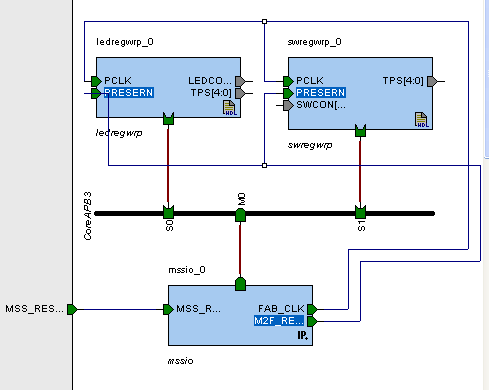

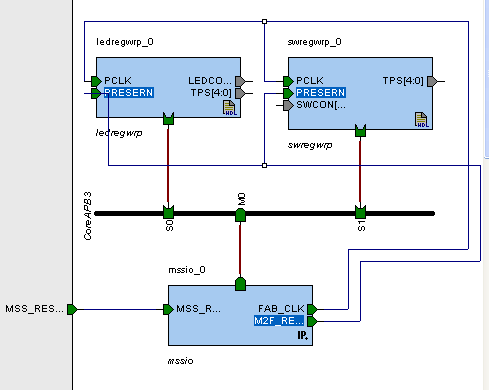

Connect Resets

Although the PCLK and FAB_CLK have different names, the tool

assumed you

wanted to connect these. In this case it is what we intended, but be

careful when using the auto connect and be sure the connections are

correct. The reset will have to be connected manually. We need to

connect the fabric reset output from the MSS block to the preset inputs

of the register wrappers. To connect two ports or more ports, select

all the ports to be connected (control, shift, click). Right click over

one of the selected ports and select connect. The canvas will no show

the connection.

Notice that the components are all

located to one side of the canvas

and the reset connection has to be routed over one of the components.

SmartDesign has an auto component arrange feature to nicely distribute

the components. Right click in the window and select auto arrange

instances. Usually this works, but you might have to manually adjust

too. Also use the auto fit feature after auto arranging. It is this

middle icon.

Notice that the components are all

located to one side of the canvas

and the reset connection has to be routed over one of the components.

SmartDesign has an auto component arrange feature to nicely distribute

the components. Right click in the window and select auto arrange

instances. Usually this works, but you might have to manually adjust

too. Also use the auto fit feature after auto arranging. It is this

middle icon.

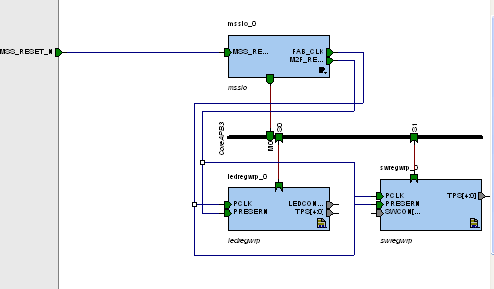

Here is what happened to the above canvas after auto arranging.

Here is what happened to the above canvas after auto arranging.

4.8

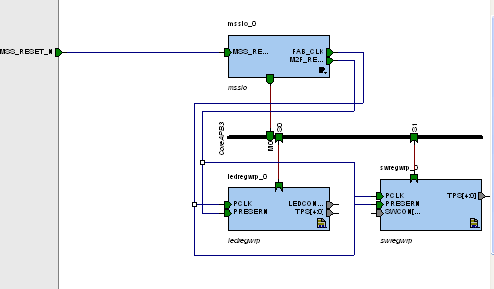

Connect LEDs, Switch

Ports and Test Points

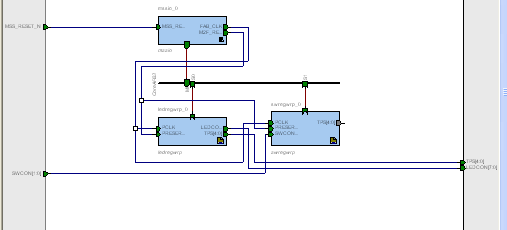

Finally we need to connect the LEDs,

Switches and Test Points to the

appropriate FPGA pins. Since the test points are identical for both

wrappers we need only connect one set. You can add FPGA ports to the

canvas by right clicking just outside the canvas and selecting add

port. However, when you have an existing port on the canvas there is a

much easier way. Select the port you wish to provide connection to,

right click and select promote to top level. This will create the

connection automatically. After adding these connections and auto

arranging instances the canvas should look like a bit like this.

4.9

Check Design and

Generate HDL for Synthesis

Before synthesis these graphical components need to be converted

to

HDL. Before doing so, we will run design check. It is the left icon

here.

You will notice that the set of unconnected test points are indicated

as floating or unconnected. This is fine since we did it intentionally.

Next generate HDL by selecting the right icon here.

You will notice that the set of unconnected test points are indicated

as floating or unconnected. This is fine since we did it intentionally.

Next generate HDL by selecting the right icon here.

One warning about the unconnected test points should be indicated. You

should see new verilog under the apb3_to_ledswreg icon in file view of

design explorer.

One warning about the unconnected test points should be indicated. You

should see new verilog under the apb3_to_ledswreg icon in file view of

design explorer.

5 Synthesize all

Components

Synthesize all the components like we did in lab 1 by selecting the

Synthesis icon and Running. Correct any errors that might occur. Before

we can synthesize, you must go back to the MSS configuration and

generate design again. If this is closed, you can open by clicking on

the icon in the hierarchy view in design explorer. If you don't do

this,

you will get a cryptic error from the Synopsis indicating that there is

an error and it can't synthesize.

6 Assign FPGA Pins

Assign FPGA pins to the LEDS, switches and Test Points like you did in

lab1. You can ignore the MSS_Reset and just leave it unassigned. It

will be automatically assigned to a fixed pin.

7 Place and Route

Run place and route like you did in lab 1.

8 Simulation

While it is possible to simulate the APB3 bus, we will skip this step

for now and verify on the kit.

9 Program FPGA

Program the FGPA like you did in lab 1.

10 Debug and Verify with

SoftConsole

We will use SoftConsole and the debugger to verify the operation of the

IO registers. We will use some GDB read/write commands via the

SoftConsole debugger connection to verify the operation of the

registers. We will also observe some of the APB3 bus control signals

with the scope.

10.1

Create a

SoftConsole Project and Debugger Session

Open SoftConsole and create an assembly project like you did

in lab 2. Use the infinite loop assembly example from lab 2.

Remember to include the link file and provide all the settings

under project-->properties. Open a debuging session

via SoftConsole as you did in lab 2.

10.2

Use GDB Commands to

Verify IO Register Function

GDB provides some basic read/write commands for accessing memory. We

could do this thru the command prompt, but we would have to go thru all

the setup you experienced in lab 2. Once the debug connection is open

in

SoftConsole, you can type any GDB command in the console window at the

bottom in Debug view.

10.2.1

Write the Led Register

The debugger in SoftConsole must

be paused for these commands to work.

The GDB command to write a register is

"set".

set

*(type *) address = contents

type

is

char, halfword or word

address

is location contents

is value to be written

When we setup the APB3

interface we discovered that register base

address was 0x40050000. Although the register is 8 bits, it

can be treated like a 32 bit value with the low order byte effective.

For example,

set *(int *) 0x40050000 = 0x55

Try writing different values

and see if the LEDs correspond to your values.

10.2.2

Read the Switch Register

The GDB command to read is

examine or simply "x". The format is:

x

address

address

is the memory location to read The default data

type is a 32 bit value

When we setup the APB3

interface we discovered that register base

address was 0x40050100. Although the register is 8 bits, it

can be

treated like a 32 bit value with the low order byte effective. For

example,

x 0x40050100

Try reading different

values and see if it corresponds to the switch

values. Remember

the switches are active low.

There are many other options

for the examine command. You can search the web for GDB quick

references for more detail.t

10.3

Use GDB Commands to

Observe the APB3 Bus Signals

Lets observe some basic APB3 bus operation with the scope. We ported

the

following signals with our Verilog code.

USER IO 1 = PCLK

USER IO 2 = PWRITE

USER IO 3 = PSEL

USER IO 4 = PENABLEUSER

USER IO 5 = PREADY

Note, it may be necessary to

power reset the kit to get the FAB clock

and in this case the APB3 clock set. You can try the RESET button or it

may be necessary to disconnect the USB power cable (nearest push

button). This will disrupt the SoftConsole debug connection. You need

to reload the configuration to recover the connection. Click on the

following icon (upper left) in the debug window and reload the

configuration

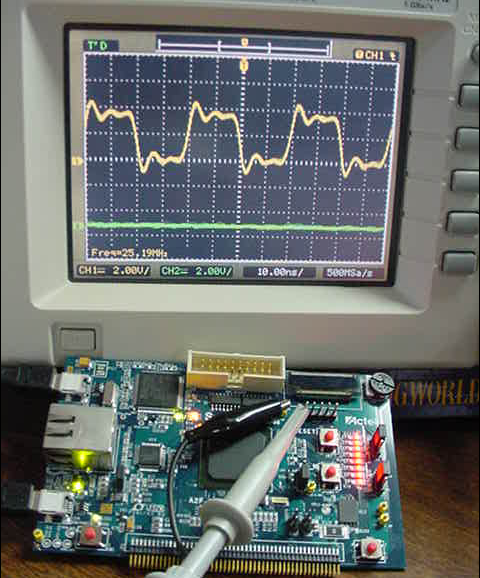

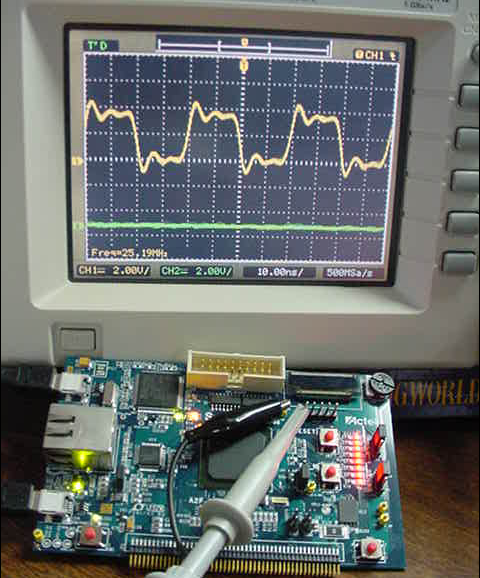

PSEL or peripheral select determines if the register is selected. Lets

monitor this signal and trigger on it going from low to high. It will

only last for one access so set the trigger up for single sweep. Use

the LED register access command:

set *(int *) 0x40050000 = 0x55

Attach the clock output to channel 2. Execute the command and see if

you can capture it on the scope. It should look like this.

PSEL or peripheral select determines if the register is selected. Lets

monitor this signal and trigger on it going from low to high. It will

only last for one access so set the trigger up for single sweep. Use

the LED register access command:

set *(int *) 0x40050000 = 0x55

Attach the clock output to channel 2. Execute the command and see if

you can capture it on the scope. It should look like this.

Notice that PSEL starts just after the rising edge of clock and last

for about 2 clock periods as indicated in the timing diagrams above.

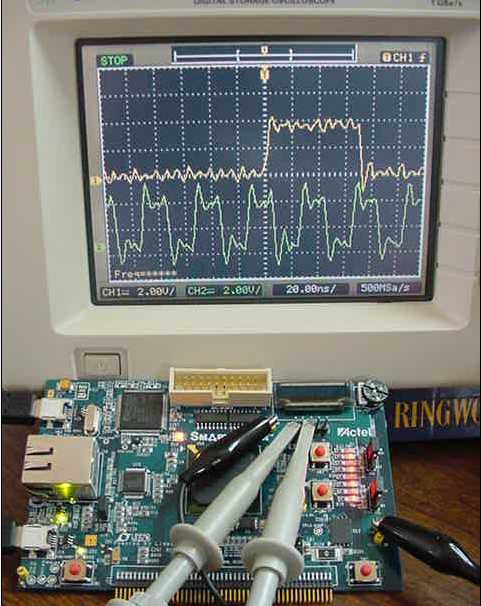

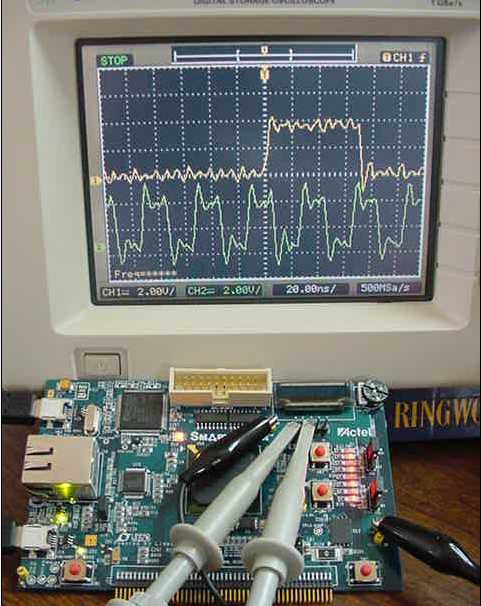

Keep PSEL on channel one, but put probe 2 on the PENABLE. Again trigger

as above. It should look something like this.

Notice that PSEL starts just after the rising edge of clock and last

for about 2 clock periods as indicated in the timing diagrams above.

Keep PSEL on channel one, but put probe 2 on the PENABLE. Again trigger

as above. It should look something like this.

Notice that PENABLE lasts for one clock period during the access phase

(2nd clock cycle) as shown in the timing diagrams above.

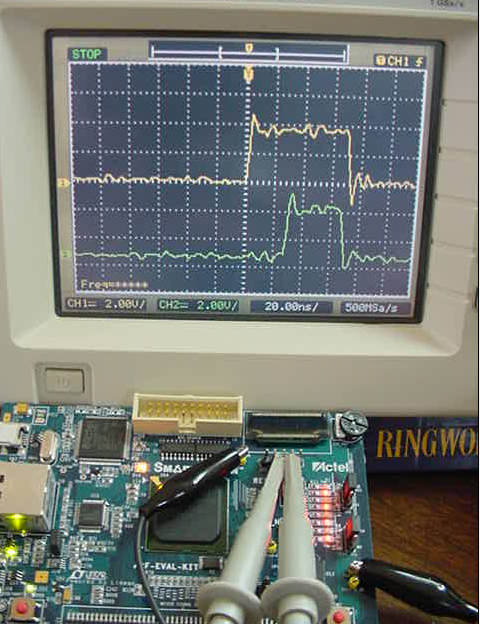

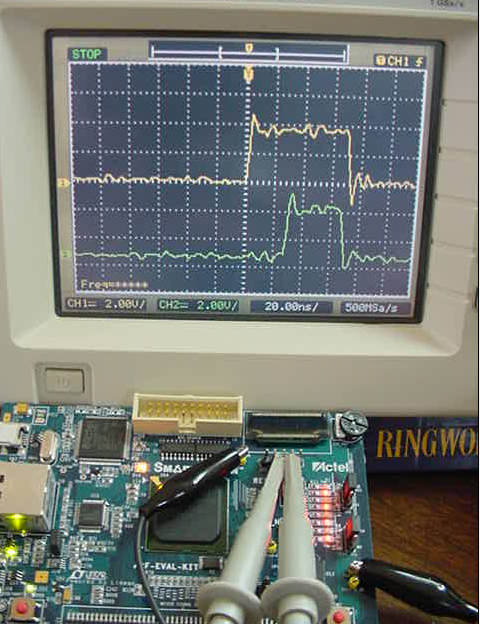

Keep PSEL on channel one, but put probe 2 on the WRITE line. Notice it

stays active (logical high) for the duration of both setup and access

cycles.

Notice that PENABLE lasts for one clock period during the access phase

(2nd clock cycle) as shown in the timing diagrams above.

Keep PSEL on channel one, but put probe 2 on the WRITE line. Notice it

stays active (logical high) for the duration of both setup and access

cycles.

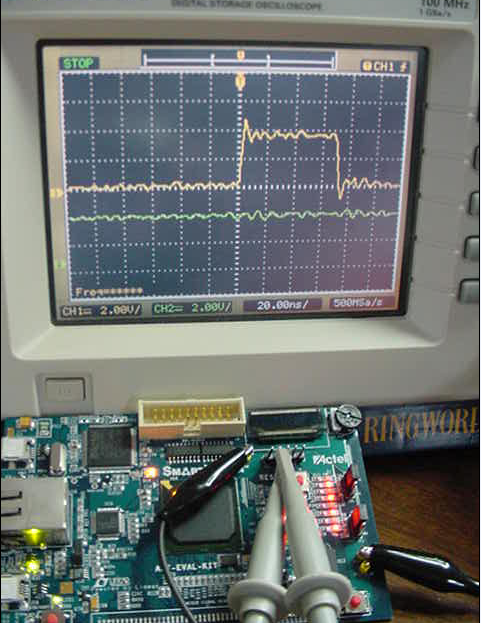

Keep the scopes connected as in the previous step, but this time try

executing the read command to the switch register.

x 0x40050100

Notice that the scope does not trigger. The PSEL that is ported on this

test point is from the LED register. It must not respond to a switch

access! If you wish to observe the PSEL for the switch register we

would have to go back and port it in SmartDesign to a user IO pin.

Keep the scopes connected as in the previous step, but this time try

executing the read command to the switch register.

x 0x40050100

Notice that the scope does not trigger. The PSEL that is ported on this

test point is from the LED register. It must not respond to a switch

access! If you wish to observe the PSEL for the switch register we

would have to go back and port it in SmartDesign to a user IO pin.

10.4

Write a Simple

Program

Lets write a simple program that reads the switches and writes the

LEDs. The program simply reads the switches and ports them to two of

the LEDs.

Assembly and Link this code. Set up a Debug connection and try the

code.

.equ STACK_TOP, 0x20000800

.equ LEDIO_REG_BASE, 0x40050000

.equ SWIO_REG_BASE, 0x40050100

.section .int_vector,"a",%progbits @ First linker code section

.global _start @ Linker entry point

_start:

.word STACK_TOP, main

@ End of int_vector section

@ Standard text section

.text

.syntax unified

.thumb

.type main, %function

main:

@ Load led register base address

movw r0, #:lower16:LEDIO_REG_BASE

movt r0, #:upper16:LEDIO_REG_BASE

@ Load switch register base address

movw r1, #:lower16:SWIO_REG_BASE

movt r1, #:upper16:SWIO_REG_BASE

loop:

@ Read switch register

ldr r3, [r1, #0]

@ Write switch values to led register

str r3, [r0, #0]

b loop

.end

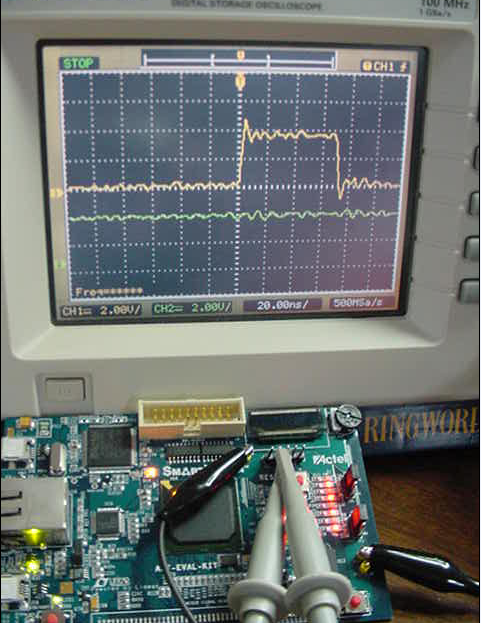

Try running the code and observing PSEL and PENABLE. You will notice

you do not have to single sweep trigger since the writes are triggering

at a regular rate.

Lab 3 Debugging Pit Falls

1) You have to stop or pause the debugger to use

FlashPro.FlashPro will not indicate a fault, but the kit will not be

identified when FlashPro starts.

2) Sometimes when running the debugger things just hang. Try reloading

the debug session or you may have to press the RESET switch on the kit.

3) If you change the settings for the FAB clock and reprogram the FPGA,

it may be necessary to power reset the kit for new FAB clock setting to

work. Disconnect the USB power cable (nearest push button) and

reconnect. This will disrupt the SoftConsole debug connection. You need

to reload the debug configuration to recover the connection.

Post-Lab Assignment

The Hardware Assignment

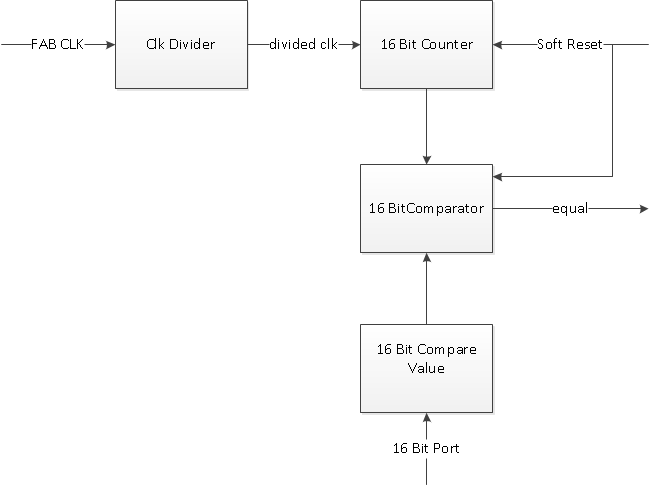

For the post lab, you will add a timer to your In-Lab hardware that can

be used by the softare via memory mapped IO registers. The timer will

count at a 100Hz and signal "equal" when a count value is

reached (Compare value == Counter value). Application software can

use the timer to provide delays

by

writing an compare value to the timer and then monitoring a status

equal bit

until the counter reaches the compare value . For example, to provide a

delay of 1 second, write a value of 100 to the compare value. A soft

reset must be

provided by the user to reset the counter and equal status bit to zero.

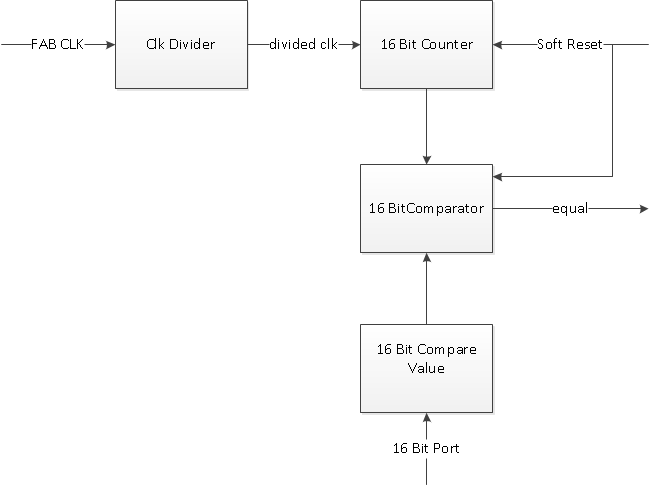

A

functional block

diagram follows.

Application Details

The

timer uses the FAB CLK as a source clock and must reduce it to

approximately 100 Hz. The

divided clock is used to source

a 16 bit counter. When the counter value and compare value are equal,

the comparator provides a signal "equal" indicating the value is

reached.

The value is held until a external reset value (soft reset) is

provided.

// timer.v

module timer (clock, compare, equal, soft_reset);

input clock;

input [15:0]compare;

input soft_reset;

output equal;

reg [15:0] counter, ncounter;

reg equal;

wire divided_clock;

reg [17:0] divide;

reg [17:0] nextDivide;

wire [15:0]nextcounter = counter + 16'd1;

//The following code divides the fabric clock to approximately 100Hz

always @*

begin

nextDivide = divide + 16'd1;

end

always @(posedge clock)

begin

divide <= nextDivide;

end

assign divided_clock = divide[17];

// This code provides the counter, comparator and software reset functions

of the timer

always @*

begin

if (soft_reset == 1)

begin

equal = 0;

end

else if (counter == compare)

begin

equal = 1;

end

else

begin

ncounter = counter + 1;

end

end

always @(posedge divided_clock or posedge soft_reset)

if (soft_reset)

begin

counter <= 0;

end

else

begin

counter <= ncounter;

end

endmodule

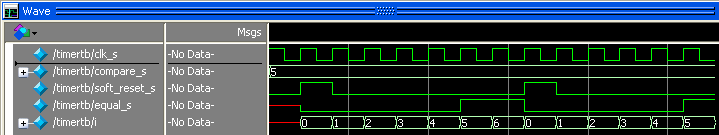

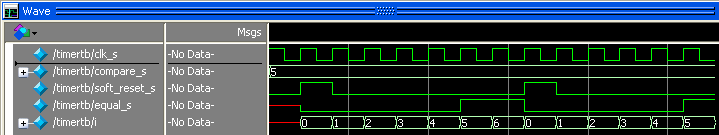

Functional Simulation of Timer Verilog

A simulation of the timer Verilog follows with the compare value set to

5. Notice that the equal value is held until reset is applied.

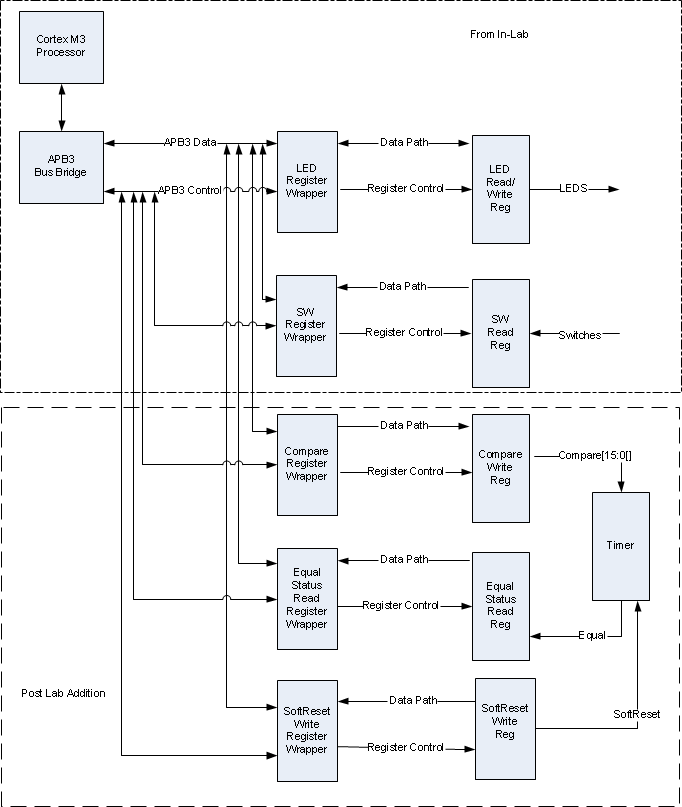

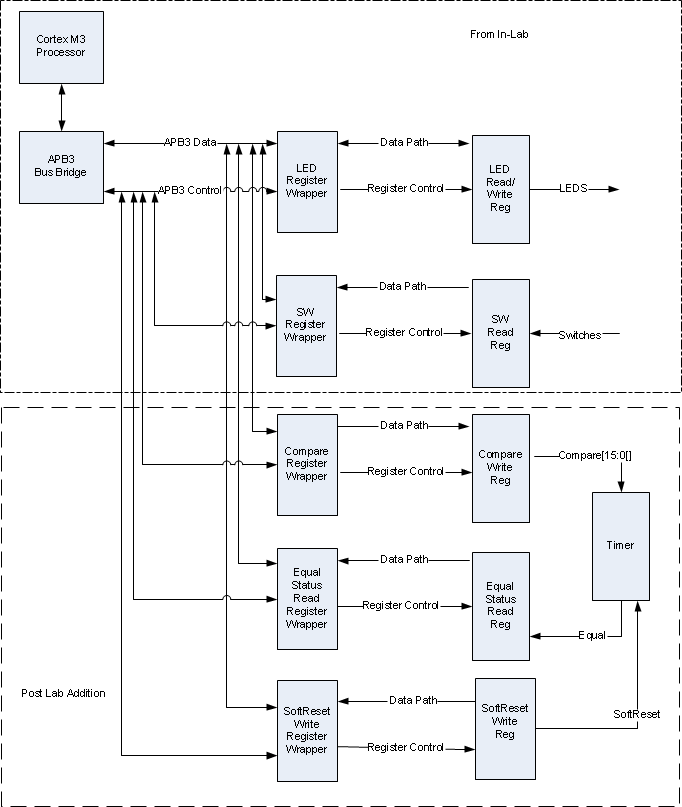

Interfacing to the APB3

The

timer can be instantiated and added to the top level canvas as a module

as you did above. The timers ports: compare, equal and soft_reset will

have to be connected to the APB3 bus via a register interface not

unlike the register interfaces provided for the switches and leds.

In this case;

however, we will provide 3 APB3 interfaced registers to support the

timer: a 16 bit write only compare register, a 1 bit read only equal

register and a 1 bit write only soft_reset register. Note, you

need to keep the switch and led registers for a software application.

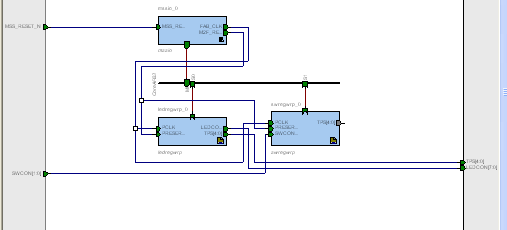

The MMIO including the timer should look a bit like this.

Soft_reset

Register Verilog

The soft reset is a software generated

reset to clear the timer counter and reset the timer equal status. The

Verilog for a Soft_reset register and

Soft_reset register wrapper follows. You will have to follow the

procedure above to instantiate the module in the top level canvas. Be

sure and connect the Soft_reset signal to the Timer module. You will

have to add another slave port the APB3 bus. Click on the

buss-->properties and add another slot.

Soft

Reset

Register

// softresetreg.v

module softresetreg( clk, nreset, wr_en, rd_en, data_in, softreset);

//Inputs Declarations

input clk; //Clock

input nreset; //active low reset

input wr_en; //Write Enable

input rd_en; //Read Enable

input [7:0] data_in; //Data Input

//output Declarations

output softreset; //path to softreset

//reg Declarations

reg [7:0] softresetreg; //the io register

wire softreset;

//map led register to leds

assign softreset = softresetreg[0];

//write softreset register

always @(posedge clk, negedge nreset)

begin : WRITE_GEN

if(nreset == 1'b0)

begin

softresetreg <= 8'h00;

end

else if(wr_en)

begin

softresetreg[0] <= data_in[0];

end

end

endmodule

Soft Reset Wrapper

// softresetwrp.v

module softresetwrp(

PCLK,

PENABLE,

PSEL,

PRESERN,

PWRITE,

PREADY,

PSLVERR,

PWDATA,

PRDATA,

SOFTRESET,

TPS);

input PCLK,PENABLE, PSEL, PRESERN, PWRITE;

input [7:0] PWDATA;

output [7:0] PRDATA

output SOFTRESET;

output PREADY, PSLVERR;

output [4:0] TPS;//test points

wire rd_enable;

wire wr_enable;

assign wr_enable = (PENABLE && PWRITE && PSEL);

assign rd_enable = (!PWRITE && PSEL); //Data is ready during first cycle to make it availble on the bus when PENABLE is asserted

softresetreg softresetreg_0 (.clk(PCLK), .nreset(PRESERN), .wr_en(wr_enable),

.rd_en(rd_enable), .data_in(PWDATA), .softreset(SOFTRESET));

assign PREADY = 1'b1;

assign PSLVERR = 1'b0;

//for the post lab you are asked to monitor the PSELs for all the MMIO with the logic anlayzer. Choose a test point that you wish

// to port the PSEL on for each MMIO wrapper

//assign TPS[0] = PCLK;

//assign TPS[1] = PWRITE;

assign TPS[2] = PSEL;

//assign TPS[3] = PENABLE;

//assign TPS[4] = PREADY;

endmodule

Timer Counter and Equal Status

Register Verilog

Complete the Verilog for the

compare and equal registers, add to your top level canvas. Hint. Use

the LED register and LED register wrapper Verilog as a model to build

the compare register and wrapper Verilog. Similarly, look at the switch

register and switch register wrapper Verilog as a model to build the

enable register and wrapper Verilog.

The Software Assignment

Write an assembly program that uses your timer, the switches and

LEDs to:

- Blink the LEDs in sequence from top to bottom (led 0 to led 7) at

a user

determined rate.

- The starting rate should be 1Hz

- The rate should increment by 1 Hz when SW1 is pressed and

released.

- The rate should decrement by 1 Hz when SW2 is pressed and

released.

- The rates should remain between 1 and 10 Hz.

A few notes:

- You can get the addresses for your timer registers by selecting

the APB3 bus in the top level canvas, right clicking and selecting

memory map.

- Consider the following process to develop your software:

- Start by blinking one LED at 1 Hz using the timer.

- Add the switch control to increase the or decrease the blink

rate.

- Modify to blink the LEDs in sequence.

- To get the switches to increase or decrease the rate in steps of

1Hz, you will have to detect the change in the switch value. Just

detecting the switch level is not sufficient. Just level detection will

result in the software detecting that the switch is pressed for several

loops decreasing or increasing the rate very quickly to one of the

boundaries. To detect a transition, you will have to keep the previous

value of the switch in a memory location or spare register and detect

if the switch has changed or not.

Post Lab Deliverables

1) Provide a coy of your

assembly code.

2 ) Demonstrate the operation of your timer and software

application on or before

the due date to one of the 373 lab instructors.

3) Answers the following questions:

- Which APB3 bus signal uniquely identifies the bus transaction for

a particular device? In general terms, what bus signals are decoded to

generate this signal?

- How many wait cycles do your MMIO registers need if any?

- The timer verilog divides the fabric clock to approximately 100Hz

by using a simple binary counter. What is the actual value in Hz?

- In the timer Verilog code, what signal edge is the timer counter

set to zero on? Why do you suppose this is necessary?

You can use the Answer

Sheet to provide the dated

signature, answers to the questions and group identification.

Extra Credit

1) Port the PSELs for all your MMIO

registers to user IO pins (test

points): Switches, LEDs and Counter registers. Connect them to 5

consecutive channels on the logic analyzer. Set the logic analyzer to

trigger on the switch register PSEL . Provide a print of the logic

analyzer view showing all the

PSELs. Identify each PSEL labeling with the register name.

References

A

quick summary of the APB3 signals:

A

quick summary of the APB3 signals:

Notice that in the design flow apb3_to_ledswreg is set as the

root in

the upper right corner.

Notice that in the design flow apb3_to_ledswreg is set as the

root in

the upper right corner.

Repeat the process for the other wrapper. The blocks should now

look

like this. Notice that all the APB3 signals are contained in one bus

connection.

Repeat the process for the other wrapper. The blocks should now

look

like this. Notice that all the APB3 signals are contained in one bus

connection.

Acknowledge this window and a APB3 bus connection icon will

appear in

the canvas. You may want to position it and size it. The canvas should

look like this now.

Acknowledge this window and a APB3 bus connection icon will

appear in

the canvas. You may want to position it and size it. The canvas should

look like this now.

After acknowledging the memory locations the APB3 connections

will be

made and look a bit like this.

After acknowledging the memory locations the APB3 connections

will be

made and look a bit like this.

Notice that the components are all

located to one side of the canvas

and the reset connection has to be routed over one of the components.

SmartDesign has an auto component arrange feature to nicely distribute

the components. Right click in the window and select auto arrange

instances. Usually this works, but you might have to manually adjust

too. Also use the auto fit feature after auto arranging. It is this

middle icon.

Notice that the components are all

located to one side of the canvas

and the reset connection has to be routed over one of the components.

SmartDesign has an auto component arrange feature to nicely distribute

the components. Right click in the window and select auto arrange

instances. Usually this works, but you might have to manually adjust

too. Also use the auto fit feature after auto arranging. It is this

middle icon.

Here is what happened to the above canvas after auto arranging.

Here is what happened to the above canvas after auto arranging.

You will notice that the set of unconnected test points are indicated

as floating or unconnected. This is fine since we did it intentionally.

Next generate HDL by selecting the right icon here.

You will notice that the set of unconnected test points are indicated

as floating or unconnected. This is fine since we did it intentionally.

Next generate HDL by selecting the right icon here.

One warning about the unconnected test points should be indicated. You

should see new verilog under the apb3_to_ledswreg icon in file view of

design explorer.

One warning about the unconnected test points should be indicated. You

should see new verilog under the apb3_to_ledswreg icon in file view of

design explorer.

![]()

PSEL or peripheral select determines if the register is selected. Lets

monitor this signal and trigger on it going from low to high. It will

only last for one access so set the trigger up for single sweep. Use

the LED register access command:

set *(int *) 0x40050000 = 0x55

Attach the clock output to channel 2. Execute the command and see if

you can capture it on the scope. It should look like this.

PSEL or peripheral select determines if the register is selected. Lets

monitor this signal and trigger on it going from low to high. It will

only last for one access so set the trigger up for single sweep. Use

the LED register access command:

set *(int *) 0x40050000 = 0x55

Attach the clock output to channel 2. Execute the command and see if

you can capture it on the scope. It should look like this.

Notice that PSEL starts just after the rising edge of clock and last

for about 2 clock periods as indicated in the timing diagrams above.

Keep PSEL on channel one, but put probe 2 on the PENABLE. Again trigger

as above. It should look something like this.

Notice that PSEL starts just after the rising edge of clock and last

for about 2 clock periods as indicated in the timing diagrams above.

Keep PSEL on channel one, but put probe 2 on the PENABLE. Again trigger

as above. It should look something like this.

Notice that PENABLE lasts for one clock period during the access phase

(2nd clock cycle) as shown in the timing diagrams above.

Keep PSEL on channel one, but put probe 2 on the WRITE line. Notice it

stays active (logical high) for the duration of both setup and access

cycles.

Notice that PENABLE lasts for one clock period during the access phase

(2nd clock cycle) as shown in the timing diagrams above.

Keep PSEL on channel one, but put probe 2 on the WRITE line. Notice it

stays active (logical high) for the duration of both setup and access

cycles.

Keep the scopes connected as in the previous step, but this time try

executing the read command to the switch register.

x 0x40050100

Notice that the scope does not trigger. The PSEL that is ported on this

test point is from the LED register. It must not respond to a switch

access! If you wish to observe the PSEL for the switch register we

would have to go back and port it in SmartDesign to a user IO pin.

Keep the scopes connected as in the previous step, but this time try

executing the read command to the switch register.

x 0x40050100

Notice that the scope does not trigger. The PSEL that is ported on this

test point is from the LED register. It must not respond to a switch

access! If you wish to observe the PSEL for the switch register we

would have to go back and port it in SmartDesign to a user IO pin.